Menu

Close

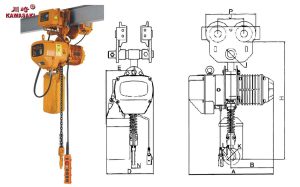

>>Limit switch:

The limit switch device is installed where the weight is lifted on and off to make the motor to

stop automatically so as to prohibit the chains from exceeding for safety

>>Support frame:

The loading support frame consists of two steel plates,which is extremely sturdy

>>Shell: It is made of light aluminum alloy shell, light but hard. The cooling fin is specially designed to ensure quick heat dissipation with the rate up to 40% and continuous service. The integral enclosed structure is applicable to places like

chemical plant and electroplate factor

>>Push button:

Waterproof push button is applied. It is light and durable

>>Hook:

It is hot forging with perfect strength that is hard to break. The operation safety of the

lower hook is ensured by its 360 degree rotation and safety tongue piece

>>Chain:

The chain shall adopt the imported FEC80 ultra heat-treatable aluminum alloy chain. It can be

safely used in poor environments such as rein sea water and chemicals.

| Model | Capacity (t) | Lifting Speed (m/min) | Lifting motor | Operating motor | ||||||||||

| Power ( kw) | Rotation speed (r/min) | Phases | Voltage (v) | Frequency (Hz/s) | Power ( kw) | Rotation speed (r/min) | Operating speed (m/min) | Phases | Voltage (v) | Frequency (Hz/s) | I-beam(mm) | |||

| KKBB0.5-01 | 0.3 | 7.8 | 1.1 | 1440 | 3 | 220-440 | 50/60 | 0.12 | 1440 | 24 | 3 | 220-440 | 50/60 | 68-130 |

| KKBB0.5-01 | 0.5 | 7.8 | 1.1 | 1440 | 3 | 220-440 | 50/60 | 0.12 | 1440 | 24 | 3 | 220-440 | 50/60 | 68-130 |

| KKBB01-01 | 1 | 6.8 | 1.5 | 1440 | 3 | 220-440 | 50/60 | 0.4 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 68-130 |

| KKBB01-02 | 1 | 3.9 | 1.1 | 1440 | 3 | 220-440 | 50/60 | 0.4 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 68-130 |

| KKBB1.5-01 | 1.5 | 8.8 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.4 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB02-01 | 2 | 6.6 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.4 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB02-02 | 2 | 3.4 | 1.5 | 1440 | 3 | 220-440 | 50/60 | 0.4 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB2.5-01 | 2.5 | 5.6 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.75 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB03-01 | 3 | 5.6 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.75 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB03-02 | 3 | 4.4 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.75 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB05-02 | 5 | 2.8 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.75 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 100-178 |

| Model | Capacity (t) | Dimensions(mm) | |||||||||||

| H | A | B | D | E | K | L | N | I | J | P | chain | ||

| KKBB0.5-01 | 0.3 | 580 | 455 | 230 | 240 | 155 | Φ31 | 29 | 20 | Φ27 | 91 | 163 | Φ6.3 |

| KKBB0.5-01 | 0.5 | 580 | 455 | 230 | 240 | 155 | Φ31 | 29 | 20 | Φ27 | 91 | 163 | Φ6.3 |

| KKBB01-01 | 1 | 650 | 520 | 260 | 300 | 176 | Φ42 | 32 | 24 | Φ31 | 115 | 221 | Φ7.1 |

| KKBB01-02 | 1 | 680 | 455 | 230 | 240 | 155 | Φ42 | 32 | 24 | Φ31 | 115 | 221 | Φ6.3 |

| KKBB1.5-01 | 1.5 | 800 | 615 | 295 | 430 | 265 | Φ49 | 40 | 30 | Φ36 | 138 | 265 | Φ10.0 |

| KKBB02-01 | 2 | 800 | 615 | 295 | 430 | 265 | Φ49 | 40 | 30 | Φ36 | 138 | 265 | Φ10.0 |

| KKBB02-02 | 2 | 835 | 520 | 260 | 300 | 236 | Φ49 | 40 | 30 | Φ36 | 138 | 265 | Φ7.1 |

| KKBB2.5-01 | 2.5 | 845 | 615 | 295 | 430 | 265 | Φ59 | 48 | 35 | Φ43 | 157 | 277 | Φ11.2 |

| KKBB03-01 | 3 | 845 | 615 | 295 | 430 | 265 | Φ59 | 48 | 35 | Φ43 | 157 | 277 | Φ11.2 |

| KKBB03-02 | 3 | 950 | 615 | 295 | 430 | 320 | Φ59 | 48 | 35 | Φ43 | 157 | 277 | Φ10.0 |

| KKBB05-02 | 5 | 1030 | 615 | 295 | 430 | 325 | Φ60 | 48 | 43 | Φ45 | 178 | 332 | Φ11.2 |

As professional electric hoist manufacturers, electric hoist suppliers, and hoist manufacturers and suppliers, we provide flexible OEM and customization services for global hoist suppliers and distributors.

Customization Options:

OEM branding; functional upgrades including explosion-proof, dust-proof, rain-proof, frequency conversion, and two-speed designs; appearance customization for each electric chain hoist; material options with T80 and T100 chains from reliable chain hoist manufacturers and chain hoist supplier partners; voltage customization from single-phase and three-phase 110V–575V; surface treatments such as spray painting, electroplating, oxidation, with chain finishes including galvanized, nickel-plated, and blackened. Packaging can be customized as required.

Minimum order quantity: 50 units.

These configurations are widely used in electric hoist for mining operations, construction, warehouses, and other heavy-duty environments, supporting advanced heavy lifting solutions.

Supply Capacity:

Monthly output of up to 5,000 electric chain hoists, serving electric chain hoist suppliers, electric chain hoist manufacturers, heavy lifting hoist suppliers, and top hoist manufacturers worldwide.

Hangzhou Apollo Lifting Equipment Co., Ltd. is one of the leading hoist manufacturers with over 30 years of experience, recognized among global hoist manufacturers, hoist lift manufacturers, and electric winch suppliers. Our Kawasaki-branded portfolio includes electric chain hoists, products from electric wire rope hoist manufacturers, manual hoists from trusted Manual hoist suppliers of industrial manual hoists, as well as Industrial hand winch solutions developed with established hand winch manufacturers and Hand winch suppliers.

We also supply industrial lifting clamps in cooperation with qualified lifting clamp manufacturers and Magnetic lifter suppliers.

As experienced crane hoist manufacturers and a reliable crane hoist supplier, we deliver complete crane systems for industrial use, including solutions from overhead crane manufacturers, industrial crane manufacturers, and leading crane manufacturers. Our offerings cover warehouse overhead crane, multiple warehouse crane types, machine shop cranes, crane for warehouse, industrial lifting crane, and systems classified under Types of crane in industry. Our equipment is widely applied as crane used in industry and crane used in construction, including construction crane for sale, projects supported by port crane manufacturers, large crane manufacturers, small cranes manufacturers, and loader crane manufacturers.

With support from certified crane parts suppliers, material lift manufacturers, and automotive car hoist manufacturer partners, we operate as a dependable crane manufacturer, long-term crane suppliers partner, and global provider of professional lifting equipment.

ISO 9001 & CE certified.

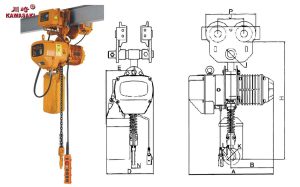

>>Limit switch:

The limit switch device is installed where the weight is lifted on and off to make the motor to

stop automatically so as to prohibit the chains from exceeding for safety

>>Support frame:

The loading support frame consists of two steel plates,which is extremely sturdy

>>Shell: It is made of light aluminum alloy shell, light but hard. The cooling fin is specially designed to ensure quick heat dissipation with the rate up to 40% and continuous service. The integral enclosed structure is applicable to places like

chemical plant and electroplate factor

>>Push button:

Waterproof push button is applied. It is light and durable

>>Hook:

It is hot forging with perfect strength that is hard to break. The operation safety of the

lower hook is ensured by its 360 degree rotation and safety tongue piece

>>Chain:

The chain shall adopt the imported FEC80 ultra heat-treatable aluminum alloy chain. It can be

safely used in poor environments such as rein sea water and chemicals.

| Model | Capacity (t) | Lifting Speed (m/min) | Lifting motor | Operating motor | ||||||||||

| Power ( kw) | Rotation speed (r/min) | Phases | Voltage (v) | Frequency (Hz/s) | Power ( kw) | Rotation speed (r/min) | Operating speed (m/min) | Phases | Voltage (v) | Frequency (Hz/s) | I-beam(mm) | |||

| KKBB0.5-01 | 0.3 | 7.8 | 1.1 | 1440 | 3 | 220-440 | 50/60 | 0.12 | 1440 | 24 | 3 | 220-440 | 50/60 | 68-130 |

| KKBB0.5-01 | 0.5 | 7.8 | 1.1 | 1440 | 3 | 220-440 | 50/60 | 0.12 | 1440 | 24 | 3 | 220-440 | 50/60 | 68-130 |

| KKBB01-01 | 1 | 6.8 | 1.5 | 1440 | 3 | 220-440 | 50/60 | 0.4 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 68-130 |

| KKBB01-02 | 1 | 3.9 | 1.1 | 1440 | 3 | 220-440 | 50/60 | 0.4 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 68-130 |

| KKBB1.5-01 | 1.5 | 8.8 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.4 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB02-01 | 2 | 6.6 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.4 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB02-02 | 2 | 3.4 | 1.5 | 1440 | 3 | 220-440 | 50/60 | 0.4 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB2.5-01 | 2.5 | 5.6 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.75 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB03-01 | 3 | 5.6 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.75 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB03-02 | 3 | 4.4 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.75 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB05-02 | 5 | 2.8 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.75 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 100-178 |

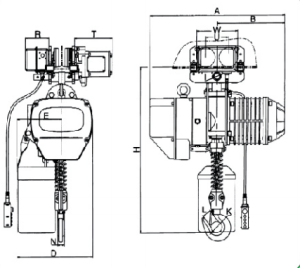

| Model | Capacity (t) | Dimensions(mm) | |||||||||||

| H | A | B | D | E | K | L | N | I | J | P | chain | ||

| KKBB0.5-01 | 0.3 | 580 | 455 | 230 | 240 | 155 | Φ31 | 29 | 20 | Φ27 | 91 | 163 | Φ6.3 |

| KKBB0.5-01 | 0.5 | 580 | 455 | 230 | 240 | 155 | Φ31 | 29 | 20 | Φ27 | 91 | 163 | Φ6.3 |

| KKBB01-01 | 1 | 650 | 520 | 260 | 300 | 176 | Φ42 | 32 | 24 | Φ31 | 115 | 221 | Φ7.1 |

| KKBB01-02 | 1 | 680 | 455 | 230 | 240 | 155 | Φ42 | 32 | 24 | Φ31 | 115 | 221 | Φ6.3 |

| KKBB1.5-01 | 1.5 | 800 | 615 | 295 | 430 | 265 | Φ49 | 40 | 30 | Φ36 | 138 | 265 | Φ10.0 |

| KKBB02-01 | 2 | 800 | 615 | 295 | 430 | 265 | Φ49 | 40 | 30 | Φ36 | 138 | 265 | Φ10.0 |

| KKBB02-02 | 2 | 835 | 520 | 260 | 300 | 236 | Φ49 | 40 | 30 | Φ36 | 138 | 265 | Φ7.1 |

| KKBB2.5-01 | 2.5 | 845 | 615 | 295 | 430 | 265 | Φ59 | 48 | 35 | Φ43 | 157 | 277 | Φ11.2 |

| KKBB03-01 | 3 | 845 | 615 | 295 | 430 | 265 | Φ59 | 48 | 35 | Φ43 | 157 | 277 | Φ11.2 |

| KKBB03-02 | 3 | 950 | 615 | 295 | 430 | 320 | Φ59 | 48 | 35 | Φ43 | 157 | 277 | Φ10.0 |

| KKBB05-02 | 5 | 1030 | 615 | 295 | 430 | 325 | Φ60 | 48 | 43 | Φ45 | 178 | 332 | Φ11.2 |

As professional electric hoist manufacturers, electric hoist suppliers, and hoist manufacturers and suppliers, we provide flexible OEM and customization services for global hoist suppliers and distributors.

Customization Options:

OEM branding; functional upgrades including explosion-proof, dust-proof, rain-proof, frequency conversion, and two-speed designs; appearance customization for each electric chain hoist; material options with T80 and T100 chains from reliable chain hoist manufacturers and chain hoist supplier partners; voltage customization from single-phase and three-phase 110V–575V; surface treatments such as spray painting, electroplating, oxidation, with chain finishes including galvanized, nickel-plated, and blackened. Packaging can be customized as required.

Minimum order quantity: 50 units.

These configurations are widely used in electric hoist for mining operations, construction, warehouses, and other heavy-duty environments, supporting advanced heavy lifting solutions.

Supply Capacity:

Monthly output of up to 5,000 electric chain hoists, serving electric chain hoist suppliers, electric chain hoist manufacturers, heavy lifting hoist suppliers, and top hoist manufacturers worldwide.

Hangzhou Apollo Lifting Equipment Co., Ltd. is one of the leading hoist manufacturers with over 30 years of experience, recognized among global hoist manufacturers, hoist lift manufacturers, and electric winch suppliers. Our Kawasaki-branded portfolio includes electric chain hoists, products from electric wire rope hoist manufacturers, manual hoists from trusted Manual hoist suppliers of industrial manual hoists, as well as Industrial hand winch solutions developed with established hand winch manufacturers and Hand winch suppliers.

We also supply industrial lifting clamps in cooperation with qualified lifting clamp manufacturers and Magnetic lifter suppliers.

As experienced crane hoist manufacturers and a reliable crane hoist supplier, we deliver complete crane systems for industrial use, including solutions from overhead crane manufacturers, industrial crane manufacturers, and leading crane manufacturers. Our offerings cover warehouse overhead crane, multiple warehouse crane types, machine shop cranes, crane for warehouse, industrial lifting crane, and systems classified under Types of crane in industry. Our equipment is widely applied as crane used in industry and crane used in construction, including construction crane for sale, projects supported by port crane manufacturers, large crane manufacturers, small cranes manufacturers, and loader crane manufacturers.

With support from certified crane parts suppliers, material lift manufacturers, and automotive car hoist manufacturer partners, we operate as a dependable crane manufacturer, long-term crane suppliers partner, and global provider of professional lifting equipment.

ISO 9001 & CE certified.

mechanical braked Dual braking system is safe and reliable

>>Limit switch:

The limit switch device is installed where the weight is lifted on and off to make the motor to

stop automatically so as to prohibit the chains from exceeding for safety

>>Support frame:

The loading support frame consists of two steel plates,which is extremely sturdy

>>Shell: It is made of light aluminum alloy shell, light but hard. The cooling fin is specially designed to ensure quick heat dissipation with the rate up to 40% and continuous service. The integral enclosed structure is applicable to places like

chemical plant and electroplate factor

>>Push button:

Waterproof push button is applied. It is light and durable

>>Hook:

It is hot forging with perfect strength that is hard to break. The operation safety of the

lower hook is ensured by its 360 degree rotation and safety tongue piece

>>Chain:

The chain shall adopt the imported FEC80 ultra heat-treatable aluminum alloy chain. It can be

safely used in poor environments such as rein sea water and chemicals.

>>Leading Hoist & Crane Manufacturer & Supplier | 30+ Years Expertise

As Hangzhou Apollo Lifting Equipment Co., Ltd, a leading hoist manufacturer and supplier with over 30 years of expertise, we provide comprehensive heavy lifting solutions. Our Kawasaki-branded products include electric chain hoists, wire rope hoists, manual hoists, and hand winches, serving as reliable electric hoist suppliers and chain hoist suppliers for mining, construction, and warehouse applications. We also supply industrial lifting clamps and are recognized among top crane manufacturers, offering overhead cranes, warehouse cranes, and port cranes. Committed to quality and innovation, we are your trusted partner for all industrial lifting needs. ISO9001 & CE certified.

| Model | Capacity (t) | Lifting Speed (m/min) | Lifting motor | Operating motor | ||||||||||

| Power ( kw) | Rotation speed (r/min) | Phases | Voltage (v) | Frequency (Hz/s) | Power ( kw) | Rotation speed (r/min) | Operating speed (m/min) | Phases | Voltage (v) | Frequency (Hz/s) | I-beam(mm) | |||

| KKBB0.5-01 | 0.3 | 7.8 | 1.1 | 1440 | 3 | 220-440 | 50/60 | 0.12 | 1440 | 24 | 3 | 220-440 | 50/60 | 68-130 |

| KKBB0.5-01 | 0.5 | 7.8 | 1.1 | 1440 | 3 | 220-440 | 50/60 | 0.12 | 1440 | 24 | 3 | 220-440 | 50/60 | 68-130 |

| KKBB01-01 | 1 | 6.8 | 1.5 | 1440 | 3 | 220-440 | 50/60 | 0.4 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 68-130 |

| KKBB01-02 | 1 | 3.9 | 1.1 | 1440 | 3 | 220-440 | 50/60 | 0.4 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 68-130 |

| KKBB1.5-01 | 1.5 | 8.8 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.4 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB02-01 | 2 | 6.6 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.4 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB02-02 | 2 | 3.4 | 1.5 | 1440 | 3 | 220-440 | 50/60 | 0.4 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB2.5-01 | 2.5 | 5.6 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.75 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB03-01 | 3 | 5.6 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.75 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB03-02 | 3 | 4.4 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.75 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 82-153 |

| KKBB05-02 | 5 | 2.8 | 3 | 1440 | 3 | 220-440 | 50/60 | 0.75 | 1440 | 11/21 | 3 | 220-440 | 50/60 | 100-178 |

| Model | Capacity (t) | Dimensions(mm) | |||||||||||

| H | A | B | D | E | K | L | N | I | J | P | chain | ||

| KKBB0.5-01 | 0.3 | 580 | 455 | 230 | 240 | 155 | Φ31 | 29 | 20 | Φ27 | 91 | 163 | Φ6.3 |

| KKBB0.5-01 | 0.5 | 580 | 455 | 230 | 240 | 155 | Φ31 | 29 | 20 | Φ27 | 91 | 163 | Φ6.3 |

| KKBB01-01 | 1 | 650 | 520 | 260 | 300 | 176 | Φ42 | 32 | 24 | Φ31 | 115 | 221 | Φ7.1 |

| KKBB01-02 | 1 | 680 | 455 | 230 | 240 | 155 | Φ42 | 32 | 24 | Φ31 | 115 | 221 | Φ6.3 |

| KKBB1.5-01 | 1.5 | 800 | 615 | 295 | 430 | 265 | Φ49 | 40 | 30 | Φ36 | 138 | 265 | Φ10.0 |

| KKBB02-01 | 2 | 800 | 615 | 295 | 430 | 265 | Φ49 | 40 | 30 | Φ36 | 138 | 265 | Φ10.0 |

| KKBB02-02 | 2 | 835 | 520 | 260 | 300 | 236 | Φ49 | 40 | 30 | Φ36 | 138 | 265 | Φ7.1 |

| KKBB2.5-01 | 2.5 | 845 | 615 | 295 | 430 | 265 | Φ59 | 48 | 35 | Φ43 | 157 | 277 | Φ11.2 |

| KKBB03-01 | 3 | 845 | 615 | 295 | 430 | 265 | Φ59 | 48 | 35 | Φ43 | 157 | 277 | Φ11.2 |

| KKBB03-02 | 3 | 950 | 615 | 295 | 430 | 320 | Φ59 | 48 | 35 | Φ43 | 157 | 277 | Φ10.0 |

| KKBB05-02 | 5 | 1030 | 615 | 295 | 430 | 325 | Φ60 | 48 | 43 | Φ45 | 178 | 332 | Φ11.2 |