In the world of heavy lifting, hoists are a total lifesaver. They move big, heavy stuff up and down without a hitch and keep things safe. Two popular kinds are the electric chain hoist and the electric wire rope hoist. Both are fantastic for lifting heavy loads, but they’ve got their own quirks that make them better for different jobs. This article dives into what sets these hoists apart. We’ll help you figure out which one’s the best fit for your needs.

Design and Construction

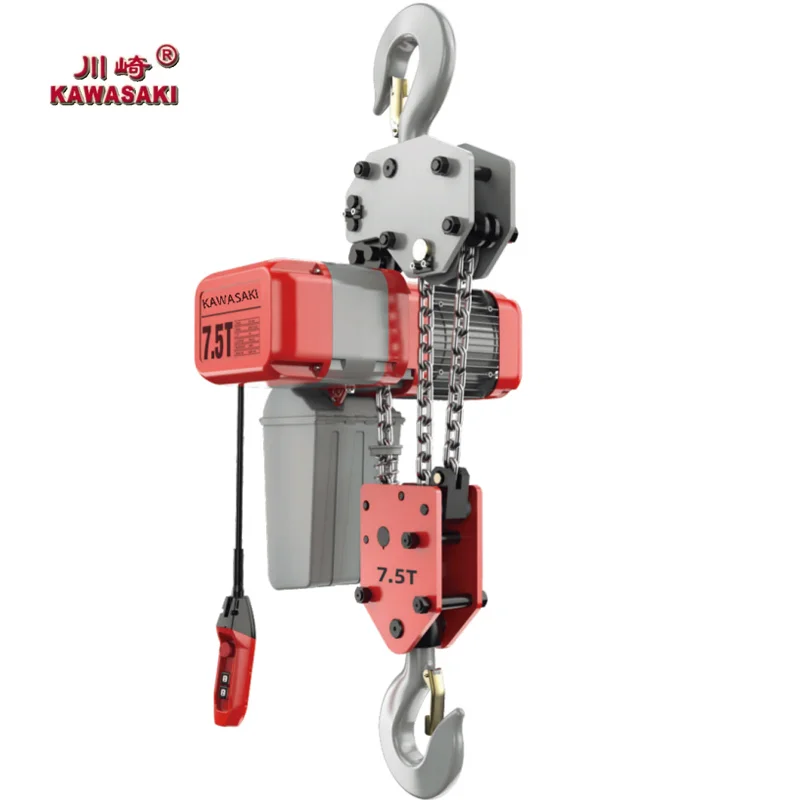

Electric Chain Hoist

An electric chain hoist is a tool that uses a chain to lift and lower heavy stuff. It’s got an electric motor that pulls the chain through a sprocket system. The chain is made of tough alloy steel. So, it’s strong and can handle all sorts of lifting tasks. Its small size makes it perfect for tight spots like warehouses, workshops, or small factories.

Key Features of Electric Chain Hoists:

- Small size: Great for tiny, cramped spaces.

- Super strong: Built with tough alloy steel chains.

- Budget-friendly: Usually cheaper than wire rope hoists.

- Easy to use: Simple to operate and keep in good shape.

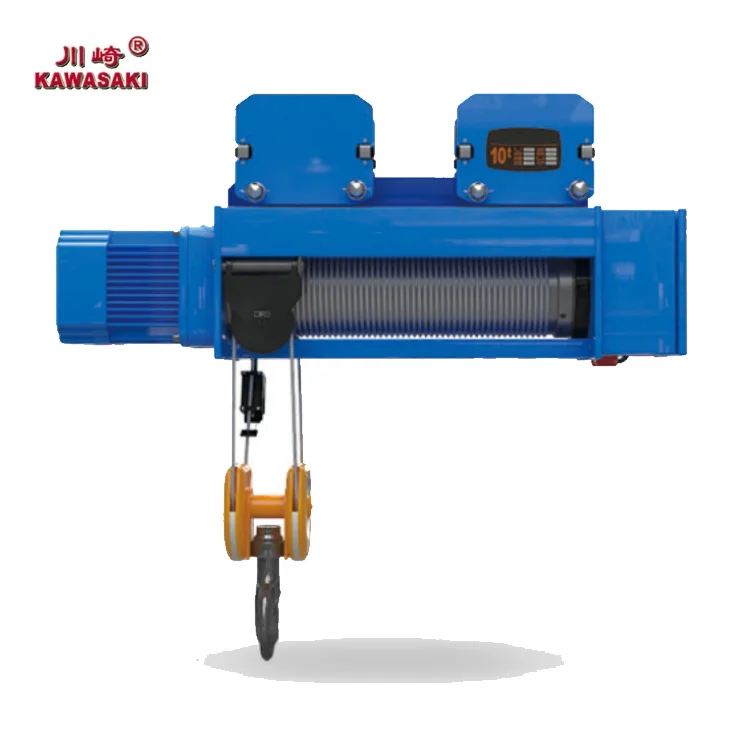

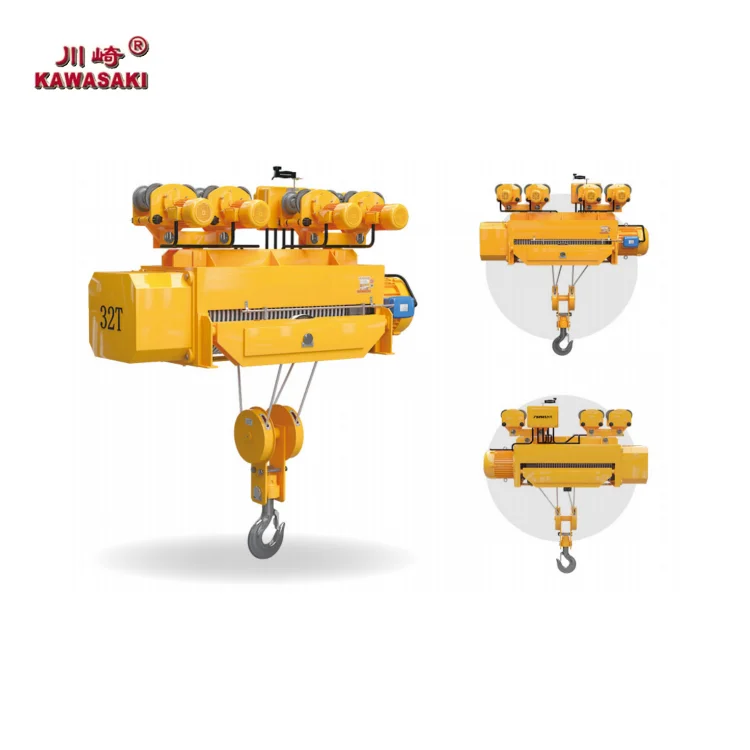

Electric Wire Rope Hoist

The electric wire rope hoist are made of steel wire rope. These rope wraps around the drum. Then the motor control the drum rotate. Rotation direction determines items up or down.

Key Features of Electric Wire Rope Hoists:

- Heavy-duty strength: Fantastic for lifting big, heavy things.

- Long reach: Can hoist stuff way up high.

- Really tough: The wire rope lasts a long time.

- Perfect for outdoors: Holds up in rough conditions.

Performance and Application Differences

Load Capacity

One big difference is how much weight these hoists can handle. An electric chain hoist is built for lighter stuff, usually from 500 kg to 5 tons. It’s awesome for jobs that don’t need crazy heavy lifting but still want solid results.

Electric wire rope hoists, on the other hand, are for heavy-duty work. They can lift from 5 tons to over 100 tons, depending on the model. That’s why they’re used in places like construction, mining, or big factories where you need to move large, heavy stuff safely.

Lifting Height

Electric chain hoists suit low-altitude lifting operations. Because they can lift to about 10 meters. This feature makes them great for indoor jobs in small spaces, like warehouses.

Electric wire rope hoists has higher lifting altitud. They often can lift past 20 meters. That’s why they’re usually used in outdoor works.

Speed and Precision

When it comes to speed, electric chain hoists are a bit slower. Their chain setup is great for careful, precise lifting, which is perfect for jobs where you need to handle stuff gently. But that slower pace can be a drag in fast-paced, high-volume jobs.

Electric wire rope hoists are faster and more efficient. They’re made for quick lifting without messing up safety or accuracy. That makes them awesome for big jobs where speed matters a lot.

Duty Rating and Frequency

Electric chain hoists are designed for light to medium tasks. They’re great for occasional lifting in places like small factories or warehouses where you don’t lift all day.

Electric wire rope hoists are built for non-stop action in tough settings. They can handle tons of lifting without wearing out fast.

Maintenance and Durability

Electric Chain Hoist Maintenance

Electric chain hoists are pretty easy to keep in shape. The chain isn’t as sensitive to things like bad weather, so it’s tough in some conditions. Regular maintenance just means checking the chain for wear and adding some grease to keep things running smoothly.

Electric Wire Rope Hoist Maintenance

Electric wire rope hoists need more attention. The wire rope can wear out, so you gotta check it often for fraying or rust. You also need to grease the rope and drum to keep friction low and make it last longer. These hoists might need more specialized care because the wire rope setup is a bit trickier.

Cost and Budget Considerations

Electric Chain Hoist Cost

Electric chain hoists are usually cheaper to buy. That makes them a great pick for businesses with tight budgets or jobs that don’t need heavy lifting. They’re also easier to maintain, which saves you money over time.

Electric Wire Rope Hoist Cost

Electric wire rope hoists cost more upfront, but they’re worth it for big jobs. Their ability to lift heavier stuff and last longer makes the extra cost pay off. Maintenance can be pricier because of the wire rope system, but their long life and strong power make them a smart choice for heavy industries.

Applications and Use Cases

Chain Hoist Applications

Electric chain hoists are fantastic for places like logistics, warehouses, or smaller factories. They’re great for lifting things like small machines, car parts, or lighter construction materials.

In 2024, the warehouse sector accounted for 35% of electric chain hoist installations globally, driven by automation trends and the need for compact lifting solutions in logistics and e-commerce. (Source: verifiedmarketreports.com)

Wire Rope Hoist Applications

Electric wire rope hoists are suitable for heavy-duty work, such as in the construction and mining industries. They are also used in offshore operations.

Check your needs and talk to experts like APOLLO today, to make sure you get the right equipment.

FAQs

Q: What is the difference between a chain hoist and a winch hoist?

A: As mentioned earlier, hoists can only lift loads up and down vertically, while winches are more versatile when it comes to the direction of load travel. Since winches use wire rope and hoists more commonly use chains, winches are better for long-distance applications, while hoists are better for short lifts.

Q: Can an electric chain hoist handle heavy-duty lifting?

A: Electric chain hoists are usually for lighter to medium jobs. For heavy stuff like construction or mining, a wire rope hoist is the better choice.

Q: How often should I maintain a wire rope hoist?

A: Wire rope hoists need regular checks. Look at the rope for damage, grease the rope and drum, and check the mechanical parts. You gotta do this often, especially if you’re using it a lot.