Choosing the right electric hoist company is not just about comparing prices or scanning a catalog. For industries that rely on safe, efficient lifting—construction, manufacturing, shipyards, even agriculture—the brand behind the equipment matters as much as the machine itself. The question is, what really separates an average supplier from a company you can trust for years to come?

Let’s break it down into the things that actually make a difference when buying and using electric hoists.

Why does company history matter in electric hoists

Long-term manufacturing experience

A company that has been producing hoists for decades usually knows where the weak spots are. APOLLO, part of HSY International Group, has been around since 1986 and carries the Kawasaki hoist brand. That means more than 35 years of real-world testing, customer feedback, and engineering upgrades. For buyers, that history translates into fewer breakdowns on site and less time worrying about repairs.

Proven brand reputation

Reputation in this industry isn’t built on ads; it’s built on consistent deliveries. Kawasaki hoists have earned recognition in Asia, Europe, and the Middle East because they perform in tough conditions—from humid shipyards in Singapore to dust-heavy factories in Indonesia. If people keep buying the same brand for decades, it says something.

Consistent quality control

A long history also gives a company time to refine its quality system. APOLLO has ISO9001 and CE/GS certifications, which sound like paperwork until you realize they mean every hoist is tested under strict protocols. A client once joked that APOLLO’s inspection team is tougher than the crane operators who’ll eventually use the hoists—and honestly, that’s exactly what you want.

How do product ranges reflect company strength

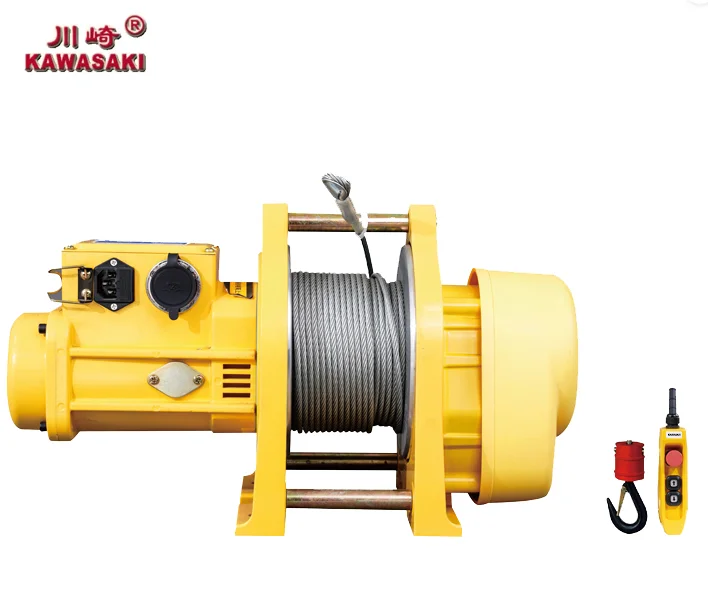

Wide choice of electric winches

A single-product company is risky because your needs change. APOLLO’s Kawasaki Electric Hoist Electric Winch is just one of many in their catalog. The winch offers steady lifting power for repetitive operations and can be customized for voltage or environmental conditions. Having such variety signals that the company is ready to serve multiple industries, not just one niche.

Advanced wire rope hoist options

For heavier or higher lifts, APOLLO provides the Kawasaki Electric Hoist Electric Wire Rope Hoist DC. This isn’t your basic warehouse helper; it’s built for serious industrial environments where you need both capacity and reliability. Customers often use it in large construction projects where downtime costs thousands per hour.

Specialized solutions for heavy lifting

Beyond standard designs, APOLLO develops hoists like the Kawasaki Electric Wire Rope Hoist LES, with European-style engineering. It’s a good fit for clients in markets that demand not only power but also compliance with EU safety norms. The LES model represents how the company tailors products for different regions, which not every manufacturer bothers to do.

What role does customization play in electric hoists

Flexible voltage and material options

No two worksites are the same. APOLLO allows custom voltage from 110V single-phase to 575V three-phase, making their hoists usable across markets from North America to the Middle East. Chains can be ordered in T80 or T100 steel, and surface finishes vary from galvanized to blackened, depending on whether the equipment will live indoors or outdoors.

OEM and brand identity service

Not every buyer wants the Kawasaki name on the casing. APOLLO offers OEM branding, so distributors can put their own label on the machines. That service is surprisingly important in B2B: dealers in Malaysia or South Korea can present the hoist under their own identity while still relying on APOLLO’s engineering.

Tailored appearance and packaging

Even packaging gets attention. Some buyers prefer color boxes for retail, others want sturdy wooden crates for shipping to construction sites. It’s a small detail, but companies that pay attention to these things usually care about bigger issues too, like meeting delivery schedules.

How important is safety and certification

International standard compliance

Electric hoists are dangerous if poorly built. Certifications like CE and GS aren’t decorative stickers; they prove the machine can handle overloads, sudden stops, or electrical fluctuations without failing. APOLLO builds with this in mind, which is why their hoists pass international audits repeatedly.

Advanced protection functions

Modern hoists need features such as overload protection, automatic limit switches, and in some cases explosion-proof casings. APOLLO integrates these as options across models. For instance, if a hoist is destined for a petrochemical plant, it can be built with explosion-proof protection from the start.

Rigorous factory testing

Every unit goes through load testing before leaving the factory. A buyer in Europe once mentioned that the APOLLO hoist they received had been tested at 200% of its rated capacity. Overkill? Maybe. But when you’re lifting tens of tons over a worker’s head, that extra assurance doesn’t feel like overkill at all.

Why does after-sales support define reliability

One-year warranty service

Machines break—that’s reality. What matters is how quickly the manufacturer responds. APOLLO provides a one-year warranty and doesn’t hide behind fine print. Customers have reported replacement parts shipped within days, not months.

Accessory and parts supply

Hoists need chains, hooks, limit switches, and sometimes entire gearboxes replaced after years of use. APOLLO keeps these parts available, which is crucial for long-term ownership. Too many smaller factories sell you a hoist but disappear when you need spares.

Technical and training support

Not every buyer has experienced technicians. APOLLO offers video guidance and catalogs for training, which saves buyers from trial-and-error mistakes. A small factory in Thailand shared how their new operators learned faster with APOLLO’s support material than with local training.

How does global presence build trust

Active distribution network in Asia

APOLLO’s Kawasaki hoists are already sold through agents in Singapore, Japan, Malaysia, Thailand, Indonesia, and South Korea. That means buyers don’t have to worry about being the “first experiment” in their region.

OEM partnerships worldwide

Beyond its own brand, APOLLO supplies hoists as OEM products to global partners. These partnerships show confidence from other businesses, who wouldn’t risk their name on unreliable gear.

Strong export capacity

With monthly production of up to 5,000 chain hoists, APOLLO can handle both small custom orders and bulk shipments. That’s a scale you simply don’t see from many competitors.

Which Kawasaki products highlight these strengths

Electric winch with reliable motor power

The Kawasaki Electric Winch offers straightforward, rugged performance. It’s often chosen for repetitive lifting jobs, where downtime isn’t an option.

Wire rope hoist DC with versatile performance

The DC model is versatile, covering everything from factory floors to construction sites. It’s known for its balance of power and durability.

Wire rope hoist LES with European design

The LES stands out with a European engineering approach, designed for customers who demand high standards of safety and compliance.

Conclusion

So, what makes the best electric hoist company stand out? It’s not one single thing—it’s the combination of history, variety, customization, safety, support, and global reach. APOLLO, with its Kawasaki range of electric hoists, checks all of these boxes. For buyers, that means fewer headaches, smoother operations, and equipment that actually lasts.

FAQs

Q1. What industries use Kawasaki electric hoists most often

They are commonly used in construction, shipbuilding, manufacturing, logistics, and even agricultural processing plants. Anywhere heavy loads need to be lifted safely and repeatedly.

Q2. Can APOLLO customize hoists for extreme environments

Yes. Options include explosion-proof casings for petrochemical sites, dust-proof designs for cement plants, and rain-proof protection for outdoor construction.

Q3. How long does delivery usually take

For standard models, delivery can be as quick as a few weeks depending on order size. Custom OEM designs may take longer, but APOLLO’s monthly capacity of 5,000 units helps keep lead times under control.