In industrial and construction settings, the selection of appropriate lifting equipment is a critical decision that directly impacts operational efficiency, workplace safety, and long-term costs. Among the fundamental choices facing equipment managers and engineers is whether to utilize manual or electric hoists for material handling tasks. This decision should be primarily guided by two key factors: usage frequency and load capacity requirements.

Understanding the relationship between these operational parameters and hoist technology is essential for optimizing material handling processes. While manual hoists offer simplicity and cost advantages for certain applications, electric hoists provide automation and labor savings that become increasingly valuable with frequent use. Similarly, load capacity requirements dictate not only the size and type of hoist but also influence safety considerations and operational protocols.

This comprehensive guide examines how usage frequency and load capacity should inform your choice between manual and electric hoists, providing detailed analysis, practical recommendations, and decision matrices for various operational scenarios. By applying the principles outlined in this document, organizations can make informed equipment selections that align with their specific operational needs and budgetary constraints.

Understanding Usage Frequency as a Selection Criterion

Defining Usage Frequency Categories

Usage frequency refers to how often a hoist is employed in daily operations, typically measured in lifts per day or operational hours. We can categorize usage into three primary levels:

- Low Frequency:Occasional use (less than 10 lifts per day or less than 1 hour of operation daily)

- Medium Frequency:Regular use (10-30 lifts per day or 1-3 hours of operation daily)

- High Frequency:Constant or intensive use (more than 30 lifts per day or over 3 hours of operation daily)

Note: These categories serve as general guidelines. The specific nature of operations, including lift height, precision requirements, and operator fatigue factors, may shift the boundaries between categories.

Manual Hoists and Usage Frequency

Manual hoists, including lever hoists (come-alongs) and chain blocks, are operated entirely through human power. Their suitability varies significantly based on usage frequency:

Advantages for Low-Frequency Applications:

- No Electrical Requirements:Manual hoists can operate in environments without power sources or where electricity poses safety hazards

- Lower Initial Investment:Typically 30-50% less expensive than comparable electric models

- Simpler Maintenance Protocols:Fewer moving parts and no electrical components reduce maintenance complexity

- Portability and Flexibility:Lighter weight and compact design facilitate use in various locations

- Precise Control:Operators can achieve fine positioning through direct manual control

Limitations with Increased Frequency:

- Operator Fatigue:Physical strain becomes significant with repeated use, potentially leading to safety issues

- Slower Operation Cycles:Manual operation typically results in slower lifting speeds

- Higher Long-Term Labor Costs:Increased personnel time required for lifting operations

- Inconsistent Performance:Human variability can lead to inconsistent operation, especially with fatigue

- Limited Productivity:Not suitable for production environments requiring rapid, repeated lifts

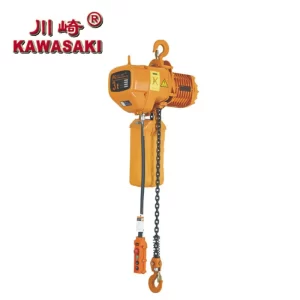

Electric Hoists and Usage Frequency

Electric hoists utilize motorized systems for lifting operations, making them particularly suited for frequent use scenarios:

Benefits for Medium to High-Frequency Applications:

- Reduced Operator Fatigue:Minimal physical effort required, enhancing safety and consistency

- Faster Operation:Electric motors provide significantly higher lifting and lowering speeds

- Higher Productivity:Faster cycle times increase throughput in production environments

- Consistent Performance:Standardized operation reduces variability between lifts

- Automation Potential:Can be integrated with control systems for semi or fully automated operation

- Reduced Labor Costs:Lower personnel requirements for lifting operations

Considerations for Low-Frequency Use:

- Higher Initial Acquisition Costs:Typically 50-100% more expensive than manual alternatives

- Power Dependency:Require reliable electrical sources, limiting deployment options

- More Complex Maintenance:Electrical components and more complex mechanisms require specialized maintenance

- Potential Underutilization:Capabilities may exceed requirements for infrequent applications

- Installation Requirements:Often need structural assessments and professional installation

Load Capacity as a Determining Factor

Understanding Load Capacity Requirements

Load capacity refers to the maximum weight a hoist can safely lift under specified conditions. Accurate assessment of load requirements is crucial for both safety and operational efficiency. We categorize load capacities as follows:

- Light Duty:Up to 2 tons (4,000 lbs)

- Medium Duty:2 to 10 tons (4,000 to 20,000 lbs)

- Heavy Duty:10 to 20 tons (20,000 to 40,000 lbs)

- Extra Heavy Duty:Over 20 tons (40,000+ lbs)

Safety Note: Always select hoists with rated capacities exceeding your maximum anticipated loads. Industry standards typically recommend a safety factor of at least 5:1 for manual hoists and 4:1 for electric hoists relative to the rated capacity.

Manual Hoists and Load Capacity

Manual hoists are available in various capacity ranges, with specific considerations for different load classes:

Suitability for Light to Medium Loads:

- Excellent Control:Direct operator feedback allows precise positioning of lighter loads

- Practical Operation:Mechanical advantage systems make loads up to 10 tons manageable

- Cost-Effective Solution:Provide adequate capacity at lower price points for many applications

- Versatility:Available in various configurations for different load ranges

Challenges with Heavy Loads:

- Increased Physical Effort:Operation becomes strenuous with heavier weights

- Safety Concerns:Operator fatigue increases risk of accidents with heavy loads

- Slower Operation:Heavier loads significantly reduce operational speed

- Practical Limitations:Beyond certain weight thresholds (typically 10-15 tons), manual operation becomes impractical

- Positioning Difficulties:Fine control becomes challenging with very heavy loads

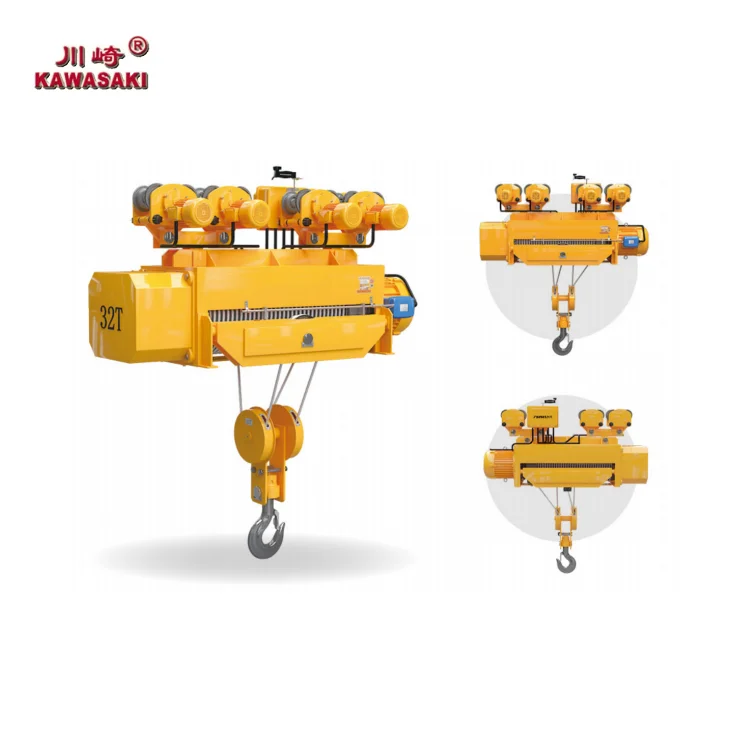

Electric Hoists and Load Capacity

Electric hoists excel in handling a wide range of load capacities with minimal operator effort:

Advantages Across All Capacity Ranges:

- Consistent Performance:Electric power provides uniform lifting regardless of load weight

- Reduced Physical Strain:Minimal operator effort required, even with maximum loads

- Broad Capacity Range:Available from light duty (0.25 tons) to extra heavy duty (100+ tons)

- Advanced Safety Features:Built-in overload protection, limit switches, and braking systems

- Precision Control:Variable speed options allow precise load positioning

Economic Considerations:

- Higher Initial Investment:Justified for frequent heavy lifting applications

- Return on Investment:Labor savings and productivity gains often offset higher acquisition costs

- Specialized Models:Available for extreme capacity requirements with appropriate safety margins

- Total Cost of Ownership:Despite higher upfront costs, may offer better value for high-usage scenarios

Integrated Decision Matrix: Frequency vs. Load Capacity

| Usage Frequency / Load Capacity | Light Duty (Up to 2 tons) | Medium Duty (2-10 tons) | Heavy Duty (10-20 tons) | Extra Heavy Duty (20+ tons) |

| Low Frequency (<10 lifts/day) |

Manual hoists recommended Cost-effective solution with adequate performance |

Manual hoists typically sufficient Consider electric if positioning precision is critical |

Consider electric for operator safety Manual possible but requires careful risk assessment |

Electric hoists generally required Manual operation impractical and unsafe |

| Medium Frequency (10-30 lifts/day) |

Either option viable Base decision on labor costs and precision needs |

Electric hoists often preferred Better productivity and reduced operator fatigue |

Electric hoists recommended Manual operation becomes physically demanding |

Electric hoists essential Only electric provides practical, safe operation |

| High Frequency (>30 lifts/day) |

Electric hoists recommended Labor savings justify higher initial cost |

Electric hoists strongly recommended Essential for productivity and operator safety |

Electric hoists essential Manual operation not feasible for production environments |

Specialized electric hoists required May need custom solutions for specific applications |

Additional Selection Considerations

Operational Environment Factors

Beyond frequency and capacity, several environmental factors influence hoist selection:

- Power Availability:Electric hoists require reliable power sources; manual hoists offer flexibility in remote locations

- Space Constraints:Manual hoists often have smaller footprints and require less clearance

- Environmental Conditions:Specialized models available for harsh environments (corrosive, explosive, extreme temperatures)

- Safety Requirements:Both types offer various safety features; electric hoists typically have more comprehensive systems

- Noise Considerations:Manual hoists operate silently; electric hoists generate operational noise

- Mobility Needs:Portable applications may favor manual hoists; fixed installations often benefit from electric models

Total Cost of Ownership Analysis

A comprehensive evaluation should consider both initial and long-term costs:

Manual Hoists

- Initial Investment:Typically 30-50% lower than electric equivalents

- Installation Costs:Minimal, often requiring only basic mounting hardware

- Labor Costs:Higher due to manual operation requirements

- Maintenance:Simpler, less frequent, and lower cost

- Energy Costs:None

- Training:Basic operation training typically sufficient

Electric Hoists

- Initial Investment:Significantly higher, especially for heavy-duty models

- Installation Costs:Higher, may require electrical work and structural assessments

- Labor Costs:Lower due to reduced operator time requirements

- Maintenance:More complex, requiring specialized technicians

- Energy Costs:Modest but present, varies with usage

- Training:More comprehensive training needed for safe operation

Case Studies and Application Examples

Warehouse Operations

In a medium-sized warehouse with periodic lifting needs up to 3 tons, manual hoists provided an economical solution. However, when operations expanded to multiple shifts with increased frequency (25-40 lifts per day), the transition to electric hoists resulted in a 40% reduction in labor costs and a 25% increase in throughput. The initial investment was recovered within 14 months through operational efficiencies.

Manufacturing Facility

A manufacturing plant handling heavy components (15-18 tons) initially used manual hoists for occasional positioning. As production demands increased to 20+ lifts per day, the switch to electric hoists not only improved safety (reducing strain-related incidents by 75%) but also reduced positioning time from 15 minutes to under 5 minutes per operation. The improved efficiency allowed the facility to increase production capacity without additional personnel.

Maintenance and Repair Shops

For maintenance facilities with infrequent, varied lifting requirements (5-15 lifts daily of weights ranging from 0.5 to 8 tons), a combination approach proved most effective. Light-duty manual hoists handled most tasks, while a single electric hoist served for heavier or more frequent lifting needs. This hybrid solution optimized both cost-efficiency and operational capability.

Construction Sites

At remote construction sites with limited power availability, manual hoists provided the necessary lifting capability for equipment placement and material handling. The portability and power independence of manual hoists made them ideal for these temporary, changing work environments despite the higher labor requirements.

Implementation Best Practices

Assessment Methodology

Proper hoist selection begins with a thorough assessment of current and anticipated needs:

- Document Load Weights:Record typical and maximum load weights, considering potential future requirements

- Track Lifting Frequency:Monitor usage patterns over representative periods to establish baseline requirements

- Consider Peak Demand:Account for seasonal variations, production spikes, and special projects

- Evaluate Future Expansion:Consider how business growth might change lifting requirements

- Assess Operator Skill Levels:Match equipment complexity to operator capabilities and training resources

- Review Safety Records:Analyze past incidents to identify potential improvement areas

Safety Considerations

Regardless of hoist type, safety must remain paramount:

- Capacity Selection:Always select hoists with capacity exceeding maximum anticipated loads

- Proper Installation:Ensure correct installation according to manufacturer specifications

- Regular Inspection:Implement scheduled inspection protocols as recommended by standards

- Comprehensive Training:Provide thorough operator training covering both normal and emergency procedures

- Maintenance Schedules:Adhere to prescribed maintenance intervals and document all service

- Environmental Assessment:Consider how temperature, humidity, and other factors may impact performance

- Load Testing:Conduct periodic load testing to verify performance and safety margins

Future Trends in Hoist Technology

The hoist industry continues to evolve with technological advancements that may influence selection criteria:

- Smart Hoists:IoT-enabled devices providing real-time usage data, predictive maintenance alerts, and operational analytics

- Improved Ergonomics:Both manual and electric hoists incorporating enhanced ergonomic designs to reduce operator strain

- Energy Efficiency:Electric hoists with regenerative braking, power-saving modes, and improved motor efficiency

- Hybrid Solutions:Systems combining benefits of both manual and electric operation, such as manually positioned electric hoists

- Advanced Materials:Lighter, stronger materials improving capacity-to-weight ratios

- Enhanced Safety Systems:Integrated monitoring, automatic overload prevention, and collision avoidance

- Modular Designs:Configurable systems that can be adapted to changing requirements

Conclusion

Selecting between manual and electric hoists requires careful consideration of usage frequency and load capacity as primary factors. Manual hoists offer cost-effective solutions for low-frequency applications with light to medium loads, while electric hoists provide operational advantages for medium to high-frequency use across all load ranges, particularly with heavier weights.

The most effective selection strategy involves a comprehensive analysis of current requirements, anticipated growth, operational environment, and total cost of ownership. Organizations should:

- Accurately assess both current and projected usage patterns

- Consider not only purchase price but long-term operational costs

- Evaluate the specific operational environment and constraints

- Prioritize safety through appropriate capacity selection and training

- Consider hybrid approaches for operations with varying requirements

As hoist technology continues to advance, the distinction between manual and electric options may evolve, but the fundamental relationship between usage patterns and equipment selection will remain critical to operational success. Regular reassessment of hoist requirements ensures that lifting equipment continues to align with changing operational needs, maintaining both efficiency and safety in material handling operations.