Introduction to Lever Hoist Safety

Understanding Lever Hoists and Their Applications

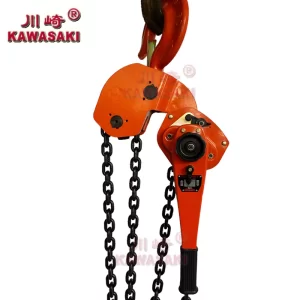

Lever hoists, commonly known as ratchet hoists or come-alongs, are versatile manual lifting devices used across numerous industries for positioning, pulling, and lifting heavy loads. These compact yet powerful tools utilize a ratchet and pawl mechanism to provide mechanical advantage, allowing a single operator to move weights that would otherwise be impossible to handle manually. The fundamental design consists of a chain, hook, lever handle, and internal gearing system that multiplies the operator’s input force.

These devices find applications in construction, manufacturing, maintenance, mining, and various industrial settings. Their portability and ability to operate in multiple orientations (vertical lifts, horizontal pulls, and even diagonal applications) make them invaluable for tasks ranging from machinery installation to structural alignment and load positioning. Understanding the capabilities and limitations of these tools is the first step toward safe operation.

The Critical Importance of Safety in Hoist Operations

Safety in lever hoist operations cannot be overstated. These tools handle substantial loads under significant tension, creating potential energy that, if released unexpectedly, can cause catastrophic failures. The consequences of safety negligence range from equipment damage to severe personal injury or fatalities. According to workplace safety statistics, improper use of lifting equipment contributes to a significant percentage of industrial accidents annually.

Beyond the obvious human cost, safety failures result in operational downtime, equipment replacement expenses, potential regulatory penalties, and increased insurance premiums. More importantly, they damage organizational safety culture and employee morale. A comprehensive safety approach addresses not just the mechanical aspects of operation but also environmental factors, human factors, and procedural controls that together create a safe working environment.

Common Hazards and Accident Patterns

Mechanical Failures

Mechanical failures typically result from equipment overload, wear and tear, improper maintenance, or using damaged components. Common failure points include:

- Chain failure:Worn, stretched, or damaged chains can fracture under load

- Hook deformation:Overloaded hooks may open up, losing their ability to retain loads

- Pawl mechanism failure:Worn pawls or ratchets can slip, causing sudden load release

- Gear damage:Internal gear teeth can strip under excessive loads or shock loading

Operator Error

Human factors contribute significantly to lever hoist accidents. These include:

- Incorrect positioning relative to the load and potential line of fire

- Improper rigging techniques and angle loading

- Failure to inspect equipment before use

- Using equipment for purposes beyond its design intent

- Inadequate communication during team lifting operations

Environmental Factors

Workplace conditions significantly impact hoist safety. Environmental hazards include:

- Poor visibility or inadequate lighting

- Unstable or uneven working surfaces

- Extreme temperatures affecting material properties

- Presence of corrosive substances that can degrade equipment

- Electrical hazards near power lines or in wet conditions

Fundamental Safety Principles

The Safety-First Mindset

Cultivating a safety-first approach means prioritizing precaution over convenience at every decision point. This mindset involves:

- Consistently questioning assumptions about equipment condition and load stability

- Resisting production pressures that might encourage safety shortcuts

- Maintaining situational awareness throughout the operation

- Speaking up about safety concerns without hesitation

- Following established procedures even when unsupervised

Risk Assessment Protocol

Before any lifting operation, conduct a thorough risk assessment that evaluates:

- Load characteristics (weight, center of gravity, stability)

- Equipment suitability and condition

- Environmental conditions and potential hazards

- Personnel competency and training adequacy

- Emergency procedures and rescue planning

Pre-Operation Equipment Inspection

Comprehensive Visual Examination

A thorough inspection should be conducted before each use, focusing on critical components:

- Hooks:Check for twisting, throat opening, wear at the saddle, and latches (if equipped)

- Chains:Look for stretched links, cracks, gouges, corrosion, or improper repairs

- Lever and handle:Ensure secure attachment and smooth operation without excessive play

- Ratchet mechanism:Verify positive engagement and absence of slipping

- Labeling:Confirm load rating labels are legible and intact

Functional Testing

After visual inspection, perform functional tests without load:

- Operate the lever through its full range to ensure smooth ratcheting

- Test both lifting and lowering functions

- Verify the free chain wheel operates smoothly

- Check that the load chain feeds properly onto the storage reel

- Confirm safety latches (if present) function correctly

Personal Protective Equipment

Appropriate PPE is essential when operating lever hoists. The specific requirements depend on the application but typically include:

- Hand protection:Heavy-duty gloves to protect against pinch points, sharp edges, and abrasion

- Foot protection:Steel-toed boots with slip-resistant soles

- Head protection:Hard hats where overhead hazards exist

- Eye protection:Safety glasses or goggles to shield against flying particles

- High-visibility clothing:When working in areas with moving equipment or traffic

Additional specialized PPE may be required for specific environments, such as respiratory protection in dusty conditions or fall protection equipment when working at height. Always conduct a job-specific hazard assessment to determine appropriate PPE requirements.

Establishing a Safety Culture

Individual safety practices are most effective when supported by an organizational safety culture. Key elements include:

- Leadership commitment to safety as a core value, not just a compliance requirement

- Comprehensive training programs with regular refreshers

- Clear reporting procedures for hazards and near-misses without fear of reprisal

- Regular safety meetings and toolbox talks addressing specific lifting hazards

- Recognition programs that reward safe behaviors and practices

When safety becomes embedded in organizational culture, it transforms from a set of rules to follow into a shared value that guides every action and decision.

Fundamental Positioning Principles

Establishing a Stable Base

The foundation of safe lever hoist operation begins with your stance. Position your feet shoulder-width apart, with one foot slightly forward to create a stable triangular base of support. Distribute your weight evenly between both feet, keeping your knees slightly bent rather than locked. This position allows for better balance and quick movement if needed.

Avoid standing with your feet too close together, as this reduces stability and increases the risk of losing balance if the load shifts unexpectedly. Similarly, an excessively wide stance can limit your mobility and reaction capability. The ideal positioning enables you to maintain control of the hoist while keeping your body out of the line of potential danger.

Maintaining the Safety Zone

Always position yourself outside the “danger zone” – the area where you would be at risk if the load were to fall or the hoist mechanism were to fail. As a general rule, stay at least 45 degrees to either side of the direct line of pull. This positioning ensures you’re not directly under the load or in the path of potential recoil should something fail.

Never position yourself between the hoist and a fixed object, as this eliminates your escape route in an emergency. Similarly, avoid standing directly in line with the load’s potential fall path. Think defensively about your positioning, considering not just where the load is, but where it could go if control is lost.

Body Mechanics and Ergonomics

Optimal Grip and Handle Operation

When operating the lever, use a firm but not overly tight grip. Your dominant hand should control the lever while your non-dominant hand stabilizes the hoist body if necessary. Position your hands so that your wrists remain straight during the ratcheting motion to prevent strain and fatigue.

Operate the lever through its full range of motion to ensure efficient operation and prevent unnecessary wear on the mechanism. Avoid short, jerky strokes which can create sudden load movements and increase stress on both the equipment and your body.

Proper Body Alignment

Maintain proper spinal alignment throughout the operation. Keep your back straight and avoid twisting your torso while operating the hoist. If you need to change your working position, reposition your entire body rather than twisting at the waist.

Your shoulders should remain relaxed and in a neutral position, not hunched upward toward your ears. This reduces fatigue and prevents muscle strain during extended operation periods. Engage your core muscles to provide additional stability and protect your lower back.

Environmental Considerations

Assessing the Workspace

Before positioning yourself to operate the hoist, conduct a thorough assessment of your surroundings. Identify potential hazards such as uneven surfaces, overhead obstructions, slippery conditions, or confined spaces that might affect your positioning options.

Ensure you have adequate lighting to clearly see the load, hoist mechanism, and your footing. Poor visibility increases the risk of missteps and improper operation. If working at height, verify that fall protection is properly employed before beginning the lift.

Accounting for Load Dynamics

Different loads present different positioning challenges. When lifting irregularly shaped objects, position yourself to account for potential shifting or swinging. For long loads, consider the pendulum effect and position yourself accordingly.

When pulling rather than lifting, position yourself to brace against the reaction force. Your stance should be oriented to resist the pull, with your weight shifted slightly away from the direction of movement. This provides better control and reduces the risk of being pulled off balance.

Advanced Positioning Techniques

Team Operation Positioning

When multiple operators are working with a single hoist or when coordinating with spotters, establish clear communication protocols and predetermined positions before beginning the operation. Each team member should understand their role and maintain visual contact with others throughout the process.

Position team members so they have clear sight lines to both the load and each other. Avoid positioning where team members are hidden from each other’s view by equipment or structures. Establish hand signals or radio communication protocols before beginning the lift.

Positioning for Different Hoist Orientations

The optimal positioning varies depending on whether the hoist is oriented vertically for lifting or horizontally for pulling. For vertical lifts, position yourself to the side of the load with a clear view of the lifting path. For horizontal pulls, position yourself at an angle that allows you to monitor both the anchor point and the load’s movement.

When operating a hoist in an overhead configuration, pay special attention to your head and hand positioning to avoid pinch points. Never position any part of your body between moving components or between the hoist and fixed structures.

Common Positioning Mistakes to Avoid

Dangerous Positioning Habits

Avoid these common but dangerous positioning errors:

- Standing directly under the load during lifting operations

- Positioning with limited escape routes

- Operating with an unstable footing or on slippery surfaces

- Reaching across the load or hoist mechanism

- Operating from ladders or unstable platforms without proper fall protection

Correcting Poor Positioning

If you find yourself in a poor position during operation, stop immediately. Release tension safely according to manufacturer instructions, reposition yourself correctly, and then resume operation. Never attempt to adjust your position while maintaining tension on the hoist, as this can lead to loss of control.

Conclusion

Proper positioning when operating a lever hoist is not merely a recommendation—it’s a critical component of workplace safety. By establishing a stable base, maintaining the safety zone, using correct body mechanics, and accounting for environmental factors, operators can significantly reduce the risk of accidents and injuries.

Remember that proper positioning extends beyond your immediate physical stance to include awareness of your surroundings, understanding of load dynamics, and consideration of team coordination. Regular training and conscious application of these positioning principles will ensure that lever hoist operations are conducted safely and efficiently, protecting both personnel and equipment.

Always consult the specific manufacturer’s guidelines for your equipment, as some positioning recommendations may vary based on hoist design and capacity. When in doubt, err on the side of caution and reposition yourself to maximize safety margins.