1. Introduction

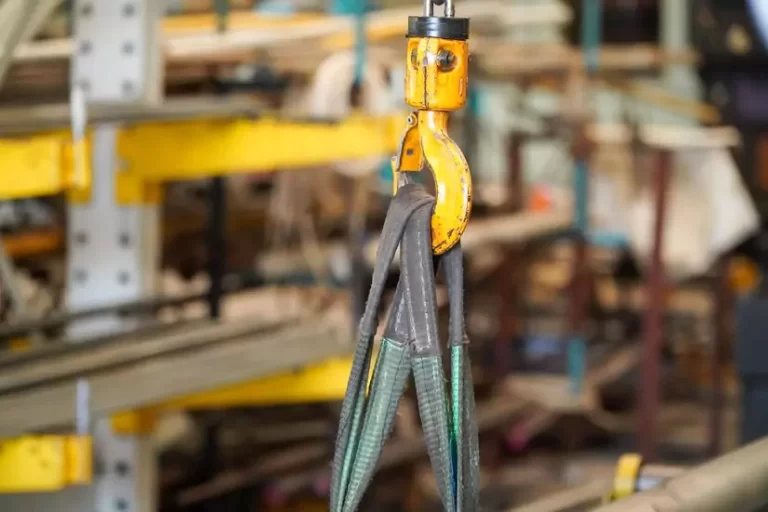

Lifting clamps are specialized mechanical devices designed to securely grip, hold, and transport heavy materials—often steel plates, beams, pipes, drums, and other industrial loads. They are a cornerstone of safe material handling in construction, shipbuilding, manufacturing, logistics, and other heavy industries.

However, not all lifting clamps are created equal. The type of clamp—whether horizontal, vertical, drum, beam, or other variants—plays a crucial role in determining the stability of the load and the safety of the lifting operation. Choosing the wrong clamp for a given task is a frequent cause of accidents, including dropped loads, equipment damage, and injuries.

This analysis examines the mechanical principles behind different clamp types, the scenarios in which they are used, and the ways in which their design characteristics influence safety and stability.

2. The Concept of Load Stability

Before discussing clamp types, it’s important to understand load stability. Load stability refers to the load’s resistance to movement (slip, swing, or rotation) during lifting, lowering, or horizontal transport.

Factors affecting stability include:

-

Center of Gravity (COG) — If the clamp’s grip is not aligned with the COG, the load can tilt or rotate.

-

Grip Force — The clamp must exert sufficient friction or mechanical lock to prevent slipping.

-

Load Orientation — Different clamps are designed for specific orientations, and using the wrong type compromises stability.

-

Dynamic Forces — Sudden starts, stops, or swings can multiply the forces acting on the clamp.

The choice of clamp type is directly tied to these stability factors.

3. Major Lifting Clamp Types and Their Influence on Stability & Safety

3.1 Vertical Lifting Clamps

Function: Designed to lift and move plates or materials in a vertical orientation, usually from a horizontal storage position to an upright position (or vice versa).

Design Features:

-

Jaws lined with hardened steel teeth for grip.

-

Often have a spring-loaded cam or lever to hold the load while tension is applied.

-

A swivel shackle allows some degree of alignment adjustment.

Stability & Safety Implications:

-

Pros: Excellent for preventing side slip when lifting vertically; strong grip along the plate edge.

-

Risks: If used for horizontal lifting, the COG shifts and the clamp can lose grip. Sudden jerks can break friction contact.

-

Safety Considerations:

-

Ensure the plate surface is clean—rust, oil, or paint can reduce friction.

-

Use multiple clamps for large plates to distribute load evenly.

-

Must not exceed the rated capacity or jaw opening range.

-

3.2 Horizontal Lifting Clamps

Function: Designed to lift and transport plates in a horizontal orientation. Often used in pairs or multiples connected by a spreader beam.

Design Features:

-

Wide jaw surface area to distribute grip force.

-

Locking mechanisms that hold plates tightly during movement.

Stability & Safety Implications:

-

Pros: Provides stable support for flat materials without tilting; reduces bending stress on the load.

-

Risks: Using a single horizontal clamp without proper spreader beams can lead to flexing or dropping of the plate.

-

Safety Considerations:

-

Always use clamps in pairs for balance.

-

Match clamp capacity to load weight and thickness.

-

Avoid lifting at angles—horizontal clamps are not designed for oblique pulls.

-

3.3 Drum Lifting Clamps

Function: Designed for handling cylindrical loads such as steel drums, barrels, or plastic chemical containers.

Design Features:

-

Curved gripping jaws that conform to drum shape.

-

May grip by the rim, body, or use a tong-style mechanism.

Stability & Safety Implications:

-

Pros: Secure grip on cylindrical surfaces; minimizes risk of drum rolling or slipping.

-

Risks: If the drum is damaged or dented, clamp grip may be uneven. Liquid sloshing inside the drum can shift the COG unexpectedly.

-

Safety Considerations:

-

Verify drum integrity before lifting.

-

For hazardous materials, ensure clamp meets spill-prevention regulations.

-

Use slow, steady lifting to prevent liquid surge.

-

3.4 Beam Lifting Clamps

Function: Designed for lifting and transporting steel I-beams, H-beams, and similar structural profiles.

Design Features:

-

Adjustable jaw width to fit various flange sizes.

-

Grip may be friction-based or mechanical lock on the beam flange.

Stability & Safety Implications:

-

Pros: Firm grip on structural members; suitable for vertical or horizontal beam positioning.

-

Risks: Off-center lifts can cause beam rotation; unsecured clamps can slide along the flange.

-

Safety Considerations:

-

Position clamps at the beam’s COG or use multiple clamps with a spreader.

-

For long beams, prevent swinging by using tag lines.

-

4. Matching Clamp Type to Load Orientation

One of the most common causes of instability is misuse of clamp type.

-

A vertical clamp used for horizontal lifting will subject the grip mechanism to shear forces it was not designed for.

-

A horizontal clamp used vertically may lose grip due to inadequate cam engagement.

-

A drum clamp designed for steel drums may slip on plastic drums unless specifically rated for them.

In short: The load orientation must dictate the clamp choice. Any deviation significantly increases the risk of instability and accidents.

5. Factors Beyond Clamp Type That Affect Stability

Even the correct clamp type can perform poorly if other conditions are not controlled:

5.1 Load Condition

-

Rust, oil, paint, or moisture can reduce friction.

-

Deformed plates or beams can create uneven grip.

5.2 Number of Clamps

-

Using a single clamp on a wide load can cause tipping or bending.

-

Multiple clamps help distribute weight evenly.

5.3 Sling & Spreader Beam Usage

-

Spreaders help maintain horizontal balance for large or long loads.

-

Incorrect sling angle can pull the clamp in unintended directions.

5.4 Operator Technique

-

Sudden acceleration can shock-load the clamp.

-

Poor communication between crane operator and riggers can lead to dangerous misalignment.

6. Safety Standards & Compliance

To ensure lifting stability and safety, clamps should comply with relevant standards such as:

-

ASME B30.20 — Below-the-Hook Lifting Devices.

-

EN 13155 — Cranes, Safety, Non-fixed Load Lifting Attachments.

-

OSHA 1910.184 — Slings and associated lifting devices.

These standards specify requirements for:

-

Design safety factors (often 4:1 or higher).

-

Load testing before use.

-

Periodic inspection intervals.

-

Operator training.

7. Case Examples: Stability & Safety Outcomes

Example 1 – Proper Clamp Use

A shipyard uses horizontal plate clamps in pairs with a spreader bar to move large steel plates. Operators check plate surfaces for oil and rust, use slow hoisting speeds, and keep workers clear of the load path. Result: No slippage, controlled movement, and minimal risk.

Example 2 – Improper Clamp Use

A construction crew uses vertical clamps to lift a plate in a horizontal position because the horizontal clamps were unavailable. The plate tips due to unbalanced COG, the clamp slips, and the plate drops—damaging nearby equipment and narrowly avoiding injury. This illustrates how clamp mismatch undermines stability.

8. Innovations in Clamp Technology for Better Stability

Recent developments aim to improve stability and safety:

-

Self-adjusting jaws that adapt to load thickness automatically.

-

Integrated load sensors to prevent overloading.

-

Anti-slip coatings to enhance grip even on oily surfaces.

-

Remote release mechanisms to eliminate the need for workers to be near suspended loads.

9. Conclusion

The type of lifting clamp chosen is not merely a matter of preference—it is a critical safety decision.

-

Vertical clamps provide stability for upright lifting but can fail if used horizontally.

-

Horizontal clamps stabilize flat loads in their original plane but must be used in pairs.

-

Drum clamps secure cylindrical loads but require careful handling with liquids.

-

Beam clamps are versatile for structural steel but must be positioned correctly to prevent rotation.

Key takeaway: The right clamp for the right orientation, combined with good surface condition, balanced load distribution, and operator training, is essential for both load stability and safety.