Ratchet tie downs, often referred to simply as ratchet straps, are indispensable tools for securing cargo during transport. Whether you are a homeowner moving furniture, a tradesperson transporting equipment, or a logistics professional handling freight, understanding how to properly use ratchet tie downs is crucial. This article explores the usage methods of ratchet tie downs and examines various scenarios in which they are most effectively applied.

What is a Ratchet Tie Down?

A ratchet tie down consists of a length of webbing (typically polyester) and a ratcheting mechanism. The webbing is durable, weather-resistant, and capable of handling heavy loads. The ratcheting mechanism allows the user to tighten the strap incrementally, which ensures that cargo is held securely in place.

Key Components:

- Strap/Webbing: Usually made from polyester due to its strength and low stretch.

- Hooks/End Fittings: These secure the ends of the strap to an anchor point (e.g., S-hooks, flat hooks).

- Ratchet Mechanism: A gear and handle system that tightens and locks the strap.

- Release Lever: Allows for easy loosening and removal of the strap.

How to Use a Ratchet Tie Down

Correct usage of a ratchet tie down ensures both safety and efficiency. Follow these steps to secure your load:

1. Anchor the Hooks

Attach the hooks or end fittings of the strap to solid anchor points. These may be on a trailer bed, truck side rails, or dedicated D-rings. Make sure the anchors are rated for the load.

2. Thread the Strap

Feed the loose end of the strap through the ratchet’s mandrel (the slot in the rotating spool). Pull the slack through until the webbing is taut, but not yet tight.

3. Tighten the Strap

Crank the ratchet handle up and down. This action rotates the mandrel and wraps the strap around it, tightening the webbing. Continue until the strap is snug and the load is secure, but avoid over-tightening, which could damage cargo or the strap.

4. Secure the Handle

Close the ratchet handle completely to lock it in place. This ensures the ratchet won’t accidentally release during transit.

5. Tidy Up Loose Ends

Wrap or tie down any excess strap to prevent it from flapping in the wind, which could lead to wear or accidents.

6. Release the Strap

To release, pull and hold the release lever and open the ratchet completely until it lays flat. This disengages the teeth of the ratchet. Then, pull the strap out of the mandrel.

Safety Tips for Using Ratchet Tie Downs

- Inspect before use: Check for frays, cuts, mold, or worn stitching.

- Don’t exceed the Working Load Limit (WLL): Each strap has a maximum load it can safely carry.

- Use edge protectors: When strapping over sharp edges, to prevent cuts.

- Avoid knots: Never tie knots in the webbing as they significantly reduce strength.

- Store properly: Keep straps dry and away from direct sunlight when not in use to prolong life.

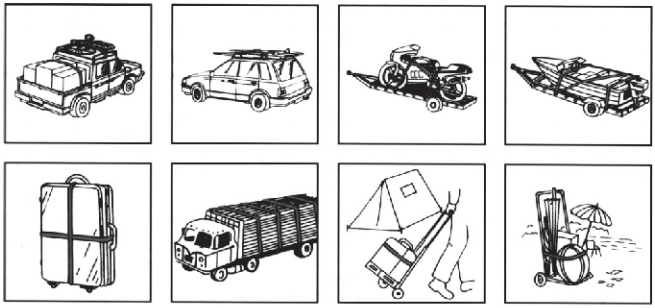

Common Scenarios for Ratchet Tie Down Usage

Ratchet tie downs are versatile and can be used in many situations. Below are some of the most common and practical applications.

1. Securing Loads in Pickup Trucks and Trailers

Perhaps the most typical use, ratchet straps are ideal for securing loads like:

- Furniture

- Appliances

- Building materials (lumber, drywall, etc.)

- Yard waste or equipment

In these cases, using multiple straps across various anchor points helps distribute tension evenly and keeps the cargo from shifting.

2. Motorcycle and ATV Transport

Specially designed ratchet tie downs can be used to secure motorcycles and ATVs for transport:

- Use soft loops around handlebars to avoid damage.

- Anchor straps at four points: two in the front and two in the rear.

- Compress the suspension slightly to prevent bouncing during transport.

3. Boats and Watercraft

Ratchet tie downs are excellent for securing boats on trailers:

- Use marine-grade straps that resist salt and moisture.

- Tie down both the bow and stern to anchor points.

- Check straps regularly as watercraft may shift during movement.

4. Moving Household Items

During a move, ratchet straps can keep furniture, boxes, and appliances from shifting in a moving truck or van:

- Wrap around items and fasten to interior anchor rails.

- Use in conjunction with blankets and padding to avoid scratches.

5. Construction and Landscaping Equipment

Transporting heavy tools like generators, cement mixers, or landscaping equipment requires strong, reliable tie downs:

- Use heavy-duty straps rated for high loads.

- Secure all sides of the equipment to prevent tilting or rolling.

6. Recreational Applications

Ratchet straps also have niche recreational uses:

- Securing camping gear (tents, coolers, canoes) to vehicle roofs or trailers.

- Tying down kayaks or paddleboards on car racks.

- Setting up temporary structures like tarps or shelters in survival scenarios.

7. Industrial and Freight Shipping

Commercial shipping uses industrial-grade ratchet tie downs to secure pallets and crates:

- High-capacity straps with greater load ratings.

- Use multiple straps across pallets to ensure even load distribution.

- Integrate with logistics tools like E-track systems inside freight containers.

8. Automotive Towing and Recovery

Tow truck operators frequently use ratchet tie downs:

- Securing vehicles to flatbeds during roadside recovery.

- Use of wheel straps or axle straps to avoid damaging suspension.

9. Agricultural Equipment Transport

Farmers and agricultural workers use tie downs to move tractors, implements, and feed:

- Requires heavy-duty ratchets for high-weight loads.

- Often used in tandem with chains and binders.

Selecting the Right Ratchet Tie Down

Choosing the appropriate strap is crucial to ensuring safety and effectiveness.

Considerations:

- Working Load Limit (WLL): The maximum load a strap can handle during use (typically 1/3 of the break strength).

- Length and Width: Longer straps accommodate larger cargo. Wider straps generally support more weight.

- End Fittings: Match the hooks or hardware to your anchor points (e.g., S-hook, J-hook, flat hook).

- Material Quality: High-quality polyester resists UV rays, mildew, and abrasion.

- Environmental Conditions: If used near saltwater or extreme heat, select weather-resistant materials.

Maintenance and Storage

Regular inspection and proper storage extend the lifespan of ratchet tie downs.

Maintenance:

- Clean with mild soap and water; avoid harsh chemicals.

- Dry thoroughly before storage.

- Lubricate the ratchet mechanism with light oil if it becomes stiff.

Storage:

- Store in a dry, cool place.

- Hang or coil the straps neatly to prevent tangles or creases.

- Use a strap organizer or storage bag for convenience.

Conclusion

Ratchet tie downs are powerful tools that combine simplicity with reliability. From moving homes to securing commercial freight, they offer a safe and effective way to prevent cargo from shifting or falling during transit. Understanding the correct usage method ensures maximum efficiency and safety. Moreover, selecting the appropriate type of strap for each scenario—from recreational use to industrial transport—enhances the versatility and durability of your tie downs.

Investing in quality ratchet tie downs and using them correctly can save time, protect property, and improve safety on the road or at the job site. Whether you’re a weekend warrior or a professional hauler, mastering the use of ratchet straps is a skill well worth having.