Manual Chain Hoists for Budget Builds or Electric for Long-Term Savings

In today’s fast-paced workshops and construction sites, picking the right chain hoist can make all the difference. Whether handling heavy loads in a garage or scaling up for industrial tasks, the choice between manual and electric models often boils down to upfront costs versus ongoing benefits. Manual versions appeal to those watching every dollar, while electric ones promise quicker workflows and fewer headaches down the line. This post breaks it down, drawing from real-world uses and spotlighting options from Apollo‘s Kawasaki line. With roots in Taiwan since 1986, Apollo brings reliable, customizable lifting gear that’s earned trust across Asia and beyond.

What Are the Main Differences Between Manual and Electric Chain Hoists?

Chain hoists come in two main flavors—manual and electric—and each suits different jobs. The big splits show up in price tags, day-to-day running, and upkeep demands. Let’s dig into those.

Initial Cost Advantages

Manual chain hoists win hands down when budgets are tight. They skip the motors and wiring, so prices stay low—often half what electric models cost. For small outfits or one-off projects, this means getting started without a huge outlay. Apollo’s CK series, for example, starts affordably and handles loads up to 20 tons, making it a go-to for basic lifts.

Electric chain hoists, though pricier at first, pack features that justify the spend over time. But more on that soon.

Operational Efficiency Gains

Electric models shine in speed and ease. Flip a switch, and they lift heavy stuff fast, cutting wait times on busy sites. Manual ones rely on hand-pulling, which works fine for lighter loads but drags on bigger jobs. Think about a warehouse crew—electric hoists let them move more in less time.

The gap widens in repetitive tasks. Electric versions, like Apollo’s KKBB, offer smooth, consistent pulls that manuals can’t match without extra effort.

Long-Term Maintenance Needs

Upkeep tells another story. Manuals have fewer parts to break, so they need less fixing—mostly just chain checks and lubrication. Electrics involve motors and controls, which might require occasional tweaks, but modern designs keep that minimal. Over years, though, electrics often prove cheaper to run, especially with energy-efficient builds.

Why Opt for Manual Chain Hoists in Budget Projects?

For folks building on a shoestring, manual chain hoists offer straightforward value. They’re tough, no-frills tools that get the job done without fancy add-ons. This makes them ideal for startups or hobbyists who need reliable lifting without breaking the bank.

Affordable CK Series Models

Apollo’s Kawasaki CK series stands out for its price-to-performance ratio. Models like the CK 1T handle everyday loads with G80-grade chains that resist wear. At a fraction of electric costs, these hoists fit garage setups or small farms perfectly. Users rave about their durability in basic tasks, from lifting engines to stacking crates.

No need for power outlets either—just pull and go.

Portable Design Features

Lightweight and compact, manual hoists slip into toolboxes easily. The CK line uses aluminum alloys in spots for easier carrying, without skimping on strength. This portability suits fieldwork where plugs aren’t handy, like remote construction or outdoor repairs.

They fold up small, too, saving space in crowded vans.

Simple Setup Process

Hook it up, and you’re ready. No wiring hassles or voltage checks—just attach to a beam and start. Apollo includes clear guides with each CK model, so even newbies set them up quick. This simplicity cuts training time, letting teams focus on the work.

How Do Electric Chain Hoists Save Time on the Job?

Time is money in lifting ops, and electric chain hoists deliver by automating the hard parts. They handle heavier loads faster, freeing workers for other tasks. In high-volume settings, this adds up to big productivity jumps.

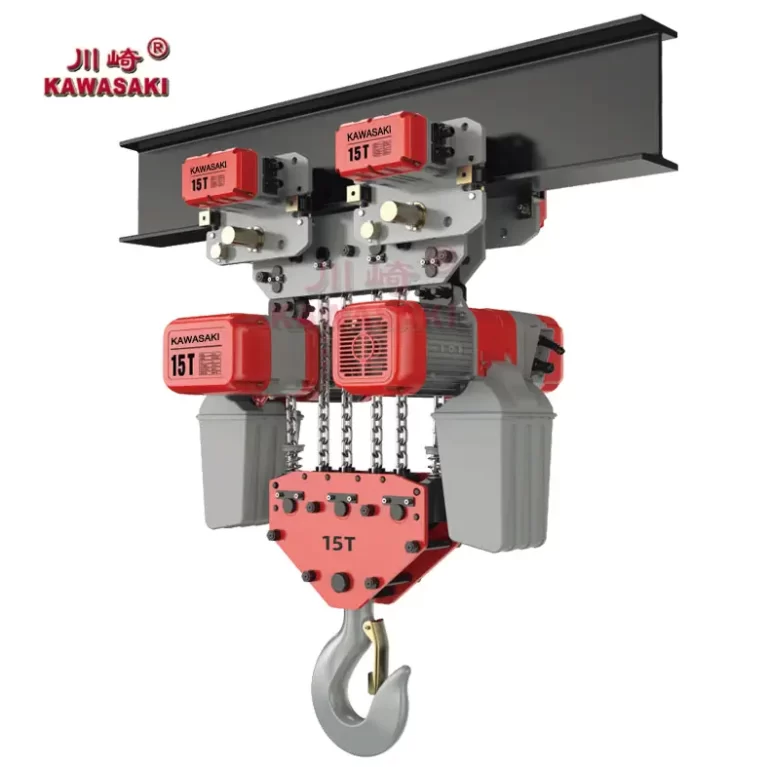

KKBB Model Speed Enhancements

Take Apollo’s Kawasaki KKBB electric chain hoist—it’s built for quick lifts with two-speed options. Handling up to several tons, it zips through cycles that would tire out manual users. Custom features like frequency conversion let you tweak speeds for precision jobs, shaving seconds off each lift.

DCER Automated Controls

The DCER model from Apollo steps it up with normal operation smarts. It includes limit switches and overload protection, so lifts stop automatically at the right spot. This cuts errors and speeds workflows—no constant watching needed. Voltage options from 110V to 575V make it flexible for global use.

Reduced Worker Fatigue

Electric hoists take the strain off people. No more endless pulling; motors do the heavy work. This means less downtime from tired crews, and safer ops too. In long shifts, like factory runs, models like DCER keep energy high, letting teams push through without breaks.

What Factors Influence Chain Hoist Selection for Your Needs?

Picking a chain hoist isn’t one-size-fits-all. Site specifics, load sizes, and power access all play in. Weigh these to match gear to your setup.

Load Capacity Requirements

Start with what you’re lifting. Manuals like CK top out at 20 tons for big jobs, but electrics handle more with ease. Apollo rates its chains T80 or T100 for strength, so check against your max loads. Underestimating leads to fails; overkill wastes cash.

Environmental Customization Options

Harsh spots need tough gear. Apollo offers dust-proof or explosion-proof tweaks on electrics like KKBB. For wet areas, rain-proof coatings protect internals. Manuals fare well outdoors too, with rust-resistant chains in blackened or galvanized finishes.

Voltage Compatibility Choices

Power matters for electrics. Apollo’s models run single or three-phase from 110V to 575V, fitting most grids. Manuals skip this worry altogether. Pick based on your site’s setup to avoid adapters or downtime.

Why Pair Beam Trolleys with Chain Hoists?

Chain hoists work best with helpers like beam trolleys for smooth moves. These add-ons let loads glide along tracks, expanding uses from fixed spots to full lines.

TBE Mobility Improvements

Apollo’s Kawasaki TBE beam trolley clamps tight to I-beams, rolling hoists where needed. Geared for easy pulls, it boosts manual or electric setups. In warehouses, this means shifting loads without resets, speeding ops.

Stable Load Handling

TBE’s design keeps things steady, even on uneven beams. High-quality clamps prevent slips, handling up to 1 ton standard. Pair it with CK or KKBB for balanced lifts that cut sway risks.

Versatile Integration Benefits

Trolleys like Kawasaki TBE fit various hoists, from chain to wire rope. Apollo’s versions work in tight spots or long runs, adapting to factories or stages. This flexibility opens doors to custom rigs.

How to Calculate Savings from Electric Over Manual Hoists?

Crunch the numbers to see electric’s edge. Factor in running costs, life span, and fixes. Over time, these stack up.

Lower Energy Consumption

Electrics sip power compared to constant manual effort. Models like DCER use efficient motors, keeping bills low. In daily use, this trims utility tabs versus hiring extra hands for manuals.

Extended Product Lifespan

Built tough, Apollo’s electrics last longer with proper care. Chains and gears in KKBB resist wear better than overworked manuals. Expect years more service, spreading costs thin.

Decreased Repair Expenses

Fewer breakdowns mean less spending on parts. Electrics have built-in safeties that prevent damage, unlike manuals prone to user errors. Apollo’s warranty covers a year, with quick accessory swaps.

What Makes Apollo’s Kawasaki Hoists a Smart Choice?

Apollo stands out in the lifting game with its Kawasaki brand. From family-run roots in Kaohsiung to global reach, it delivers quality gear backed by certs and service.

ISO and CE Certifications

All Kawasaki hoists pass ISO9001 and CE/GS checks, meeting tough safety rules. This ensures reliable performance, whether manual CK or electric KKBB. Buyers get peace of mind knowing gear holds up to standards.

OEM Customization Services

Apollo excels at tailoring. Change colors, add explosion-proofing, or tweak chains—minimum orders start at 50 for electrics. This lets brands match hoists to their look, boosting appeal.

Reliable After-Sales Support

Support doesn’t end at sale. One-year warranties, video guides, and parts service keep things running. Catalogs and agents in Asia help too, making Apollo a partner, not just a supplier.

Wrapping up, manual chain hoists suit quick, cheap starts, but electrics pay off in speed and savings for bigger ops. Apollo’s lineup, like the CK for budgets or KKBB and DCER for efficiency, covers it all.

FAQs

Q1: What’s the main advantage of a manual chain hoist over an electric one?

A: Manuals cost less upfront and need no power, perfect for simple, portable jobs.

Q2: How do I know if an electric chain hoist is worth the extra money?

A: If your site runs high-volume lifts or heavy loads daily, the time saved and less fatigue make it pay back quick.

Q3: Can Apollo customize chain hoists for specific environments?

A: Yes, options like dust-proofing or voltage tweaks let you adapt models like KKBB to tough spots.