Lever hoists, also known as ratchet hoists or come-alongs, are indispensable tools in various industries including construction, manufacturing, and logistics. These versatile devices provide mechanical advantage for lifting, pulling, and positioning heavy loads. However, like all mechanical equipment, their continued safe operation depends heavily on proper maintenance and storage practices. This comprehensive guide outlines essential procedures to ensure your lever hoist remains in optimal condition throughout its service life.

Understanding Lever Hoist Components

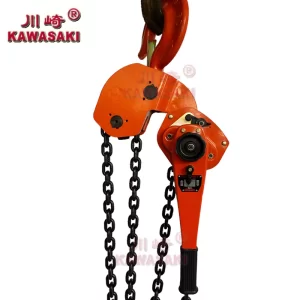

Before delving into maintenance procedures, it’s crucial to understand the key components of a typical lever hoist:

- Load chain (typically alloy steel)

- Lever handle and ratcheting mechanism

- Gears and pawls

- Hooks (load and suspension)

- Body/housing

- Braking system

Each component requires specific attention during maintenance routines to ensure the overall integrity of the tool.

Routine Maintenance Procedures

1. Regular Cleaning

After each use, thoroughly clean the lever hoist to remove dirt, debris, and contaminants. Use a stiff brush to remove caked-on material from the chain and mechanism. For more thorough cleaning, use a petroleum-based solvent to dissolve grease and stubborn deposits. Ensure all solvent residues are completely removed before applying new lubricant, as solvent can dilute fresh lubricant and reduce its effectiveness.

2. Lubrication Schedule

Proper lubrication is critical for smooth operation and preventing premature wear:

- Chain lubrication:Apply a quality chain lubricant specifically designed for lifting equipment. Ensure the lubricant penetrates between chain links.

- Internal mechanism:Apply a light machine oil to the ratchet mechanism, gears, and pivot points according to the manufacturer’s recommendations.

- Frequency:Lubricate after cleaning, before storage, and whenever the mechanism appears dry or operates roughly.

3. Inspection Protocols

Implement a rigorous inspection routine:

Pre-Use Inspection (Before each shift)

- Check hooks for deformation, cracks, or throat opening

- Inspect load chain for stretched links, cracks, or excessive wear

- Verify proper operation of the ratchet mechanism

- Test brake function with a light load

- Ensure safety latches on hooks are functional

Periodic Detailed Inspection (Quarterly or as specified by manufacturer)

- Disassemble according to manufacturer instructions

- Inspect gears for chipped teeth or excessive wear

- Check pawls for proper engagement and wear

- Measure chain for elongation beyond manufacturer specifications

- Inspect all pins and bearings for wear

Note: Maintain detailed inspection records including date, inspector name, findings, and any corrective actions taken. These records may be required for compliance with safety regulations.

Proper Storage Procedures

1. Cleaning Before Storage

Never store a dirty lever hoist. Residual contaminants can accelerate corrosion and degrade lubricants. After thorough cleaning and lubrication, ensure the hoist is completely dry before storage to prevent moisture-related damage.

2. Storage Environment

The storage location significantly impacts tool longevity:

- Climate control:Store in a dry, climate-controlled environment when possible

- Temperature stability:Avoid extreme temperature fluctuations which can cause condensation

- Protection from elements:If outdoor storage is unavoidable, use waterproof covers and elevated storage to prevent ground moisture contact

- Cleanliness:Keep storage area free from corrosive chemicals, excessive dust, and metal particulates

3. Positioning and Support

Proper positioning during storage prevents unnecessary stress on components:

- Hang hoists by their suspension hook when possible

- If shelf storage is necessary, ensure the hoist is fully supported to prevent distortion

- Never store heavy items on top of hoists

- Keep chains neatly coiled to prevent kinks and tangles

4. Protection from Corrosion

In humid or marine environments, additional corrosion protection may be necessary:

- Apply a thin film of rust-preventative oil to exposed surfaces

- Consider using vapor-corrosion inhibitors in storage containers

- For long-term storage, use desiccant packs in sealed containers

Troubleshooting Common Issues

1. Chain Issues

Problem: Chain doesn’t move smoothly or binds

Possible causes: Lack of lubrication, damaged links, foreign material in mechanism

Solution: Clean thoroughly, lubricate, inspect for damaged components

2. Slipping Load

Problem: Load slips when hoist should be holding

Possible causes: Worn pawls, damaged ratchet teeth, contaminated friction surfaces

Solution: Discontinue use immediately. Disassemble and inspect braking mechanism

3. Stiff Operation

Problem: Lever requires excessive force to operate

Possible causes: Inadequate lubrication, misalignment, damaged components

Solution: Lubricate according to manufacturer specifications. If problem persists, disassemble for inspection

When to Retire a Lever Hoist

Despite proper maintenance, all tools eventually reach the end of their service life. Retire a lever hoist immediately if you observe:

- Cracks in any structural component

- Hooks that have twisted or opened beyond manufacturer specifications

- Chain elongation exceeding the recommended limit (typically 3-5%)

- Missing or illegible capacity markings

- Irreparable damage to the braking mechanism

- Any modification or repair not performed by the manufacturer or authorized service center

Conclusion

Proper maintenance and storage of lever hoists is not merely a recommendation—it’s a critical safety requirement. Implementing a consistent maintenance program extends service life, reduces downtime, and most importantly, protects personnel from potential accidents. Always prioritize safety over convenience, and when in doubt about a hoist’s condition, remove it from service until a qualified professional can assess it. Remember that no maintenance procedure can substitute for proper operator training and conscientious use.