If you’re hunting for lifting gear that tackles tough jobs with ease, an electric rope hoist could be your answer. These machines simplify heavy tasks in warehouses, factories, and building sites. But choosing the right one can feel tricky. This guide breaks it down. We’ll cover the basics, why they stand out, and key points to consider.

What Is an Electric Rope Hoist

Before diving into options, let’s nail down what these machines are. Electric rope hoists aren’t flashy—they’re practical tools built for hard work.

Basic Definition and Components

An electric rope hoist is a powered device that lifts heavy stuff using a steel wire rope. It runs on electricity, so no hand-cranking like older hoists. Main parts include the motor, which does the tough lifting; the drum, where the rope coils; the strong, bendy wire rope; hooks to grab the load; and controls like pendants or remotes. Brakes are key—they stop things safely. Wire rope hoists are compact but tough. The rope, made of twisted steel, lasts longer than chains in some cases.

Key Operating Principles

So, how does it work? It’s pretty simple. The motor turns the drum, pulling the rope to lift the load. Press a button to lower, and it unwinds gently. Brakes kick in if power fails. You can tweak speed for careful or quick jobs. It’s all about control—too fast, loads swing; too slow, you’re wasting time.

It’s basic physics: motor power turns into lifting strength. Limit switches stop over-travel.

Common Industrial Applications

Where do these hoists shine? Warehouses use them to stack boxes high. Factories move parts along production lines. Construction sites lift beams or tools up scaffolds. They’re also big in shipyards and mines for heavy loads.

Picture an auto plant—electric rope hoists handle engine blocks easily. Or in food processing, where hygiene matters, special versions keep things clean. They fit cranes or stand alone, making them super versatile.

Why Choose an Electric Rope Hoist Over Other Types

You’ve got choices—chain hoists, manual ones, even air-powered. So why pick electric rope? It comes down to a few big benefits that make work smoother.

Superior Load Capacity

These hoists lift heavier weights than many others. Wire ropes spread stress well, handling tons where chains might struggle. Some models lift up to 250 tons, though most jobs stay under 50.

This is huge for heavy industries. Lifting steel plates all day? Extra capacity means fewer breakdowns. It’s not just max weight—it’s steady performance.

Enhanced Efficiency and Speed

Speed is a major plus. Electric rope hoists move loads faster—often feet per minute quicker than chain ones. No delays; loads zip up and down.

They’re also easy on power. Modern motors use less electricity, saving money over time. In a busy shop, that matters. Plus, operators don’t tire out—it’s just a button press.

Improved Safety Features

Safety’s no small thing. Overload protection stops lifts if they’re too heavy. Emergency stops and anti-sway tech prevent mishaps.

Unlike manual hoists, these cut down on injuries. Wire ropes hold up in rough conditions, adding reliability.

What Factors Should You Consider for Load Capacity

Load capacity isn’t just a number—it’s the core of your pick. Get it wrong, and you’re in for problems.

Maximum Weight Requirements

Figure out your heaviest load first. Add a cushion—maybe 20-50% extra. Why? It keeps things safe.

Say your max is 5 tons. Aim for a 7-10 ton hoist. Check ratings—they follow standards like ISO or CE.

Duty Cycle and Usage Frequency

How much will it run? Duty ratings like M3 or M4 in Kawasaki models tell you. Light use? Lower rating’s fine. Heavy shifts? Pick a higher one.

Constant use wears parts out fast. In busy warehouses, higher cycles keep things moving without breaks.

Overload Protection Mechanisms

Safety features are non-negotiable. Sensors stop lifts if loads are too heavy. Some even have alarms.

This isn’t extra—it’s critical. From what I’ve seen, models with adjustable protection work best for varied tasks.

How Does Lifting Height and Speed Impact Selection

Height and speed might seem small, but they shape how well the hoist fits your setup. Mess this up, and work slows down.

Required Lift Height Assessment

Measure from floor to the hook’s top point. Add extra for slings. Most hoists handle 10-30 feet, but custom ones go higher.

In tall spaces, longer ropes are vital. Short ones limit you, causing awkward setups.

Available Speed Variations

Speeds vary from slow for precision to fast for bulk. Dual-speed options—like Kawasaki’s M3/M4—offer flexibility.

Think about your pace. Need quick lifts for shipping? Go faster. Delicate work? Slower is safer.

Application-Specific Adjustments

Match the hoist to the job. Variable speed controls smooth out starts and stops. For cranes, trolley speed counts too.

These tweaks make a difference in special spots, like clean rooms or outdoor sites.

What Environmental Conditions Influence Your Choice

Your workplace can be tough—dust, heat, or risky gases. The right hoist handles it all.

Explosion-Proof Capabilities

In places like chemical plants, explosion-proof hoists are a must. Sealed motors stop sparks.

Kawasaki has these, built to safety standards. It’s about staying safe and meeting rules.

Dust and Waterproof Designs

Got a dusty warehouse or rainy site? IP-rated covers keep dirt out. Waterproofing handles wet conditions.

These features make hoists last longer. I’ve seen gear fail from dust—don’t let that happen.

Extreme Temperature Adaptability

Working in hot forges or cold storage? Hoists with special lubes and materials hold up.

From -20°C to 50°C, choose one rated for your temps. It keeps work steady all year.

Which Customization Options Enhance Performance

Standard hoists are okay, but custom touches make them fit perfectly. It’s like getting a tailored shirt.

Brand and Appearance Modifications

Want your logo on it? Need a specific color? OEM branding is simple.

Apollo Hoist makes this easy, giving your gear a sharp, professional look.

Voltage and Material Customizations

Voltages from 110V to 575V work anywhere. Galvanized ropes fight rust.

Choose based on your power setup and conditions. It’s practical stuff.

Functional Upgrades like Frequency Conversion

Add dual speeds, rain-proofing, or smooth controls with frequency drives.

These extras solve specific issues, like tricky loads or outdoor work.

Why Opt for Kawasaki Electric Rope Hoists from Apollo

Apollo Hoist, part of Taiwan’s HSY International Group, kicked off in 1986 as a family business in Kaohsiung. They’ve earned trust for reliable lifting gear, with an R&D base in Japan since 2001. Their Kawasaki brand offers quality at good prices, backed by years of know-how. As an OEM supplier with agents in Singapore, Japan, and Thailand, they understand global demands.

Proven Quality and Certifications

What makes them special? Strict testing. ISO9001 and CE/GS certifications ensure every hoist meets high standards. They test assembly, performance, and safety.

Buyers love their reliability. With 500 electric hoists monthly, they deliver without cutting corners.

Recommended Models Including Running Type and Low Static Air Variants

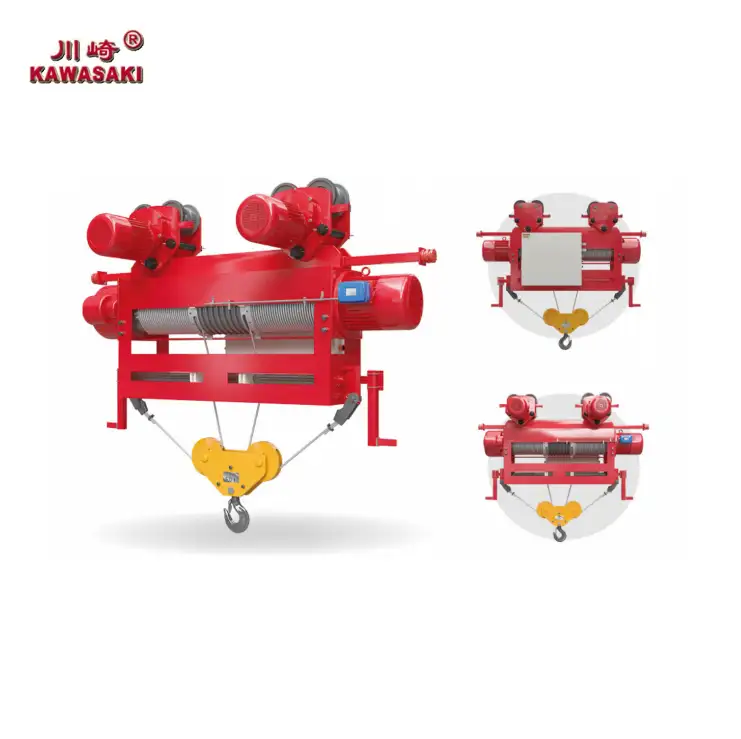

Here are some top picks. The Kawasaki Running Type Wire Rope Electric Hoist M3(CD/MD) M4(FMCD/FMMD) works great for mobile cranes—smooth movement, sturdy design.

Next, the Square Box Type Pickling and Galvanizing Steel Wire Rope Electric Hoist M3(CD/MD) M4(FMCD/FMMD)—built to resist corrosion in rough places.

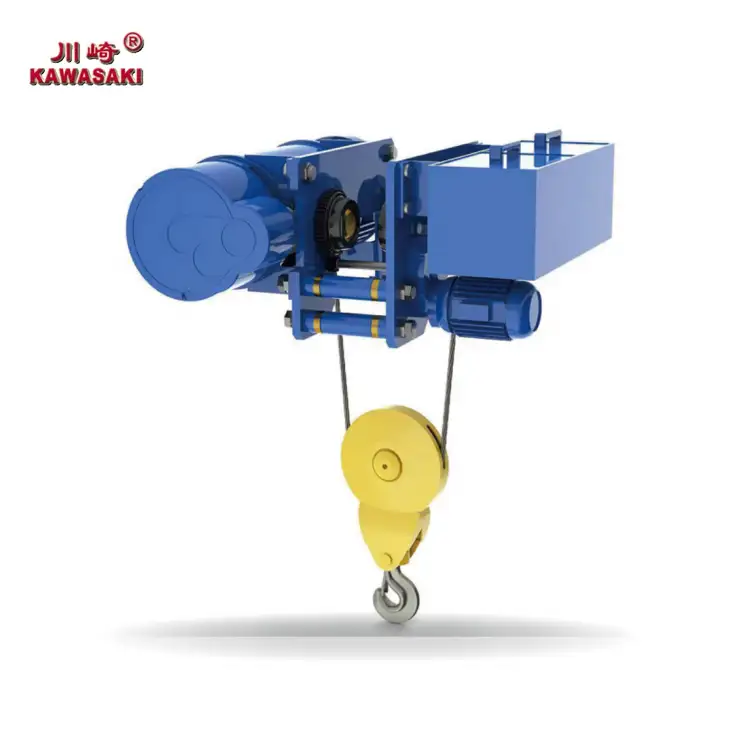

Finally, the Low Static Air Type Wire Rope Electric Hoist M3(DJCD/DJMD) M4(FMDJCD/FMDJMD)—perfect for tight spaces with low headroom.

Comprehensive After-Sales Services

Support doesn’t stop after buying. You get a one-year warranty, spare parts, video guides, and even promo catalogs.

As a family-run company, they focus on service. That builds trust—something big companies sometimes lack.

FAQs

Q1: What’s the main difference between an electric rope hoist and a chain hoist?

A: Electric rope hoists use wire ropes for quicker lifts and higher reaches, great for heavy, far-off tasks. Chain hoists are smaller and cheaper for light, short jobs but may wear out faster in hot conditions.

Q2: How often should I maintain my electric rope hoist?

A: Inspect ropes and brakes every month. Lubricate gears every three months. Get a full check by experts yearly. Stick to the maker’s guide to avoid issues.

Q3: Can I customize a Kawasaki electric rope hoist for my specific voltage?

A: Yes, they work with 110V to 575V, single or three-phase. Add explosion-proof features or color changes—minimum order 50. Talk to Apollo for details.