Taking care of a rope hoist might seem simple at first glance. But anyone who has worked in a busy warehouse, a metal workshop, or even a small fabrication shop knows it can get tricky. A rope hoist is more than just a hook and a rope. It’s a combination of chains, drums, motors, brakes, and other safety parts that all work together. If any part gets neglected, it can cause problems quickly. Apollo’s KAWASAKI hoists, are built to handle tough conditions and heavy lifting. But even the strongest machines need regular attention.

Sometimes people skip maintenance because the hoist looks fine on the surface. That’s a big mistake. Even a tiny rust spot or a small loose screw can become a major issue over time. Proper upkeep not only protects your equipment but also keeps your team safe.

Why Is Regular Rope Hoist Maintenance Important

Equipment Longevity

Regular care can significantly extend a hoist’s lifespan. For instance, a medium steel shop in Malaysia used a KAWASAKI M3(FMCD) for daily lifts up to 5 tons. Workers applied chain oil and did basic inspections weekly. Over two years, the machine ran almost nonstop with minimal downtime. Without those checks, even minor wear could have caused serious failures. Simple steps like wiping the drum and rotating the chain occasionally can make a huge difference. I remember one operator joking that their chain looked “as new as the day it arrived”—and it was true because of consistent maintenance.

Safety Assurance

Nothing spoils a workday faster than an accident. Hoist safety is critical. By regularly inspecting hooks, brakes, limit switches, and other parts, you lower the risk of incidents. Apollo hoists are CE and GS certified, but certificates do not replace hands-on inspections. A hook with a tiny crack or a slightly loose brake can be dangerous if ignored. Safety checks may feel tedious, but they prevent accidents, injuries, and costly repairs.

Performance Consistency

Have you noticed a hoist jerking or moving slower than usual? That’s often a sign it needs attention. Smooth operation isn’t just for convenience. It protects the load, prevents stress on the crane system, and keeps lifts accurate. Even small hiccups in movement can cause material to shift, which is risky in factories or construction sites. Consistent performance makes life easier for operators and prevents long-term damage to the hoist.

What Are The Key Maintenance Steps for Wire Rope Hoists

Lubrication And Cleaning

Keeping chains, ropes, and gears clean is essential. In dusty factories or outdoor job sites, dust and grime settle everywhere. Apollo recommends using a light industrial lubricant every 100 hours of use. In humid or harsh environments, more frequent lubrication is better. I once saw a dusty warehouse where operators only cleaned hoists monthly. Unsurprisingly, the ropes and gears became stiff, slowing down work significantly. Regular cleaning prevents this and keeps the hoist running quietly.

Inspection Of Hooks And Chains

Check hooks, chains, and bolts for scratches, bends, or rust. Even small cracks can lead to a snapped hook under heavy loads. Visual inspections are surprisingly effective. One operator once spotted a hairline crack on a hook during a quick glance, preventing what could have been a costly accident. Small steps like these save time, money, and stress.

Checking Electrical Components

For electric hoists, keep an eye on wiring and control panels. Loose wires, frayed cables, or water ingress can cause problems quickly. Apollo’s SZCD/SZMD series is built with reinforced insulation for high-heat conditions, but a visual check helps catch minor issues before they escalate. It’s easy to ignore electrical maintenance, especially if everything seems fine. But a little attention now can prevent a sudden breakdown later.

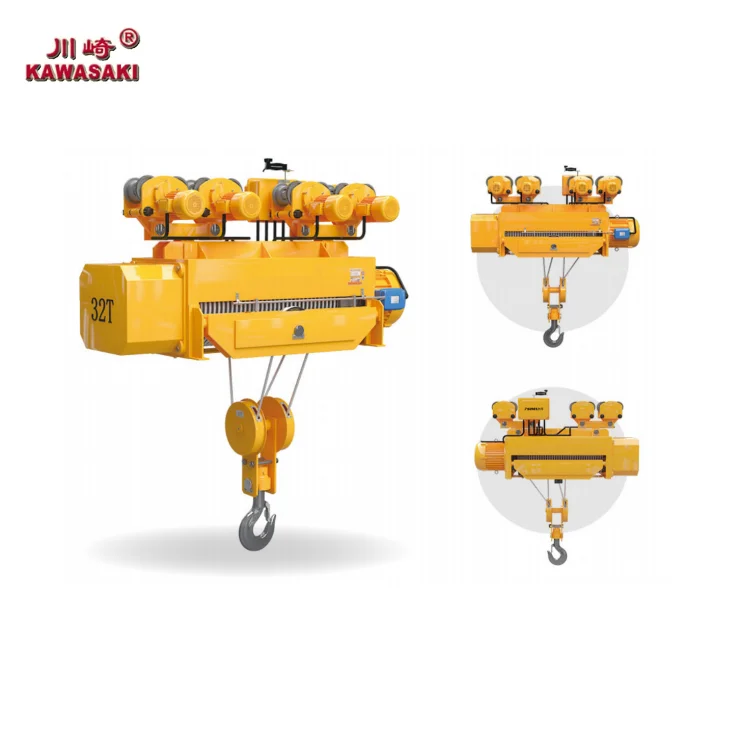

How To Maintain KAWASAKI Fixed Type Wire Rope Electric Hoist M3(CD/MD) M4(FMCD/FMMD)

Routine Cleaning And Lubrication

Focus on the drum and load chain. Wipe off dust, remove debris, and apply a thin layer of chain oil. Don’t overdo it—too much lubricant attracts dirt and grit. Apollo hoists are built for regular use, so this simple step ensures smooth lifting and long-term reliability.

Safety Device Inspection

Check brakes, hooks, and limit switches. Listen for odd noises or look for slight movements that shouldn’t be there. Apollo designed these hoists with inspection points that are easy to see, so operators can spot issues quickly. Even a small squeak can indicate a worn brake pad that might affect lifting under load.

Load Chain And Drum Maintenance

Check the drum for grooves or uneven wear. Rotating it occasionally prevents certain sections from wearing faster. Some operators skip this step and find their hoist jerks mid-lift. Don’t let that happen. Simple rotation can make the hoist run smoother for years.

How To Maintain KAWASAKI For Lifting Molten Metal Steel Wire Rope Electric Hoist SZCD/SZMD

Heat-Resistant Component Care

Lifting molten metal puts stress on parts. Heat shields, bearings, and ropes need checking. Apollo uses alloys that handle extreme heat, but frequent inspection is still necessary. Even the strongest materials can develop fatigue over time.

Hook And Chain Integrity Checks

High temperatures can weaken metal subtly. Watch for discoloration, small cracks, or unusual stretching. Foundries often forget this, assuming the hoist is fine because it’s designed for heat. But small changes can turn into serious problems if ignored.

Electrical System Inspection

Heat-resistant wiring is strong, but wear and tear can still happen. Look for scorched wires or loose terminals. Even a quick visual check saves headaches later. In one factory, a scorched terminal almost caused a short circuit—luckily, routine inspection caught it in time.

How To Maintain KAWASAKI Heavy Duty Wire Rope Electric Hoist M3(HC/HM) M4(FMHC/FMHM)

Heavy Load Handling Precautions

Before lifting heavy machinery or construction modules, check drum alignment and brakes. A minor misalignment can make the load uneven and dangerous. Heavy-duty hoists are robust, but even they have limits.

Lubrication And Cleaning

Grease bearings, wipe dust, and spray motor housings regularly. High-load hoists need more frequent care. This keeps moving parts smooth and prevents small issues from turning into big failures.

Safety And Performance Verification

Do a test lift without load first. Listen carefully for unusual sounds. Sometimes, it’s just a small adjustment. Other times, it’s an early warning of wear. A quick test prevents accidents and keeps production running smoothly.

When Should You Schedule Professional Rope Hoist Inspection

Recommended Inspection Intervals

Apollo suggests a professional inspection at least once a year, or more often for heavy or continuous use. In factories running three shifts daily, semi-annual inspections are smarter.

Signs Of Wear And Tear

Look for fraying ropes, jerky movements, odd noises, or rust spots. Early detection saves money and prevents sudden downtime.

Benefits Of Professional Servicing

A trained technician can spot hidden problems, adjust brakes, and replace worn parts before failure. Regular professional inspections complement your daily maintenance and keep the hoist reliable.

What Are Common Mistakes To Avoid During Rope Hoist Maintenance

Over-Lubrication Issues

Too much oil is not helpful. It attracts dirt and dust, especially in outdoor or dusty work sites.

Ignoring Minor Damages

Scratches, bends, or color changes often indicate bigger issues. Inspecting minor signs prevents bigger failures later.

Improper Electrical Handling

Never try to fix motors or control panels without training. Apollo hoists are tough, but electricity is risky. Follow safety rules carefully.

FAQ

Q1: How often should I lubricate my rope hoist chains?

A1: Usually every 100 hours, or weekly for heavy-duty use. Adjust depending on dusty or hot environments.

Q2: Can I use the same maintenance steps for all KAWASAKI hoist models?

A2: Basic steps work, but high-temperature or heavy-duty models like SZCD/SZMD and M3(HC/HM) need extra attention.

Q3: Is professional inspection necessary if I do daily maintenance?

A3: Yes. Daily checks catch small problems, but yearly professional inspections keep the hoist safe and reliable for the long term.