Introduction: The Power of Simple Machines

The chain hoist represents one of humanity’s oldest and most reliable mechanical innovations for lifting heavy objects. At its core, this seemingly simple device embodies principles that have been understood since antiquity yet remain fundamentally important in modern engineering and industry. The remarkable ability of a chain hoist to allow a single operator to lift loads weighing several tons with minimal effort is not magic but rather the practical application of basic physics principles, primarily the concept of mechanical advantage achieved through pulley systems.

Understanding how chain hoists work requires exploring the fundamental relationship between force, distance, and work. While these concepts might seem abstract, they have very practical implications in everything from construction and manufacturing to shipping and rescue operations. This article will examine the mechanical principles that make chain hoists so effective, focusing on how they transform small input forces into substantial lifting power.

The Fundamental Principle: Mechanical Advantage

At the heart of every chain hoist’s operation lies the principle of mechanical advantage—a concept that describes how machines can multiply force. Mechanical advantage is formally defined as the ratio of output force to input force in a system. In practical terms, it means that by using an appropriate mechanical system, a person can exert a relatively small force to move or lift a much heavier object.

The mathematical expression for mechanical advantage is straightforward: MA = Output Force / Input Force. For example, if a hoist has a mechanical advantage of 10:1, an operator needs to apply only one-tenth of the force that would be required to lift the load directly. This force multiplication doesn’t come without a trade-off, however, as well explore later in this article.

Mechanical advantage explains why we can use chain hoists to lift engines out of vehicles, position heavy machinery in factories, or hoist construction materials to upper floors of buildings—tasks that would be impossible for humans to perform directly. The chain hoist serves as a force amplifier, leveraging simple mechanical principles to extend our physical capabilities.

The Pulley System: Core Component of Mechanical Advantage

The primary mechanism through which chain hoists achieve mechanical advantage is the pulley system. A pulley is essentially a wheel with a grooved rim through which a rope or chain can run. When multiple pulleys are combined in a system, they can dramatically reduce the amount of force needed to lift a load.

In a typical chain hoist, two types of pulley arrangements are commonly used: fixed pulleys and movable pulleys. Fixed pulleys change the direction of force but don’t provide mechanical advantage, while movable pulleys—those attached to the load—do provide mechanical advantage. The combination of these pulleys creates what’s known as a block and tackle system, which forms the functional heart of most chain hoists.

In a simple pulley system with a single movable pulley, the mechanical advantage is 2:1, meaning the input force is half the output force. As more pulleys are added to the system, the mechanical advantage increases proportionally. For instance, a system with two movable pulleys provides a 4:1 mechanical advantage, while three movable pulleys offer 6:1 advantage, and so on.

How Pulleys Create Mechanical Advantage

The physics behind pulley systems is elegant in its simplicity. When you have multiple strands of chain or rope supporting a load, the weight is distributed across all these supporting strands. In a system with a mechanical advantage of 4:1, for example, the load is supported by four sections of chain, meaning each section carries only one-quarter of the total weight. The operator only needs to pull with enough force to tension one of these sections, thus requiring only one-quarter of the force needed to lift the load directly.

This distribution of force comes with a trade-off related to distance. To raise a load by one meter using a 4:1 system, the operator must pull four meters of chain through the system. This relationship between force and distance is fundamental to all simple machines and is encapsulated in the principle of conservation of energy—the work input (force × distance) equals the work output, minus small losses due to friction.

Gearing Systems: Another Layer of Mechanical Advantage

Many modern chain hoists incorporate gear systems that provide additional mechanical advantage beyond what the pulley system alone offers. These gear systems work on principles similar to those found in automobile transmissions or bicycle gear mechanisms.

Gear-based mechanical advantage relies on the relationship between the number of teeth on interacting gears. When a small gear (the driver) turns a larger gear (the driven), the larger gear rotates more slowly but with greater torque. The mechanical advantage in such a system equals the ratio of the number of teeth on the driven gear to the number on the driver gear.

In a chain hoist, these gear systems are often combined with the pulley system, creating a compound machine that multiplies the mechanical advantage from both systems. For example, if a pulley system provides a 4:1 advantage and a gear system provides a 5:1 advantage, the total mechanical advantage becomes 20:1 (4 × 5). This compound advantage explains how some heavy-duty hoists can allow a single person to lift loads of several tons.

The Trade-Off: Force vs. Distance

As mentioned earlier, the mechanical advantage provided by chain hoists comes with a trade-off between force and distance. This relationship is fundamental to all simple machines and is a direct consequence of the conservation of energy principle. Since energy cannot be created or destroyed (only converted from one form to another), the work input to a system must equal the work output, minus efficiency losses.

Work is defined as force multiplied by distance (W = F × d). Therefore, if a machine decreases the necessary force, it must increase the distance through which that force is applied. In the case of a chain hoist with a 6:1 mechanical advantage, the operator only needs to apply one-sixth of the force, but must pull the chain six times farther than the distance the load actually rises.

This trade-off is why chain hoist operation requires patience—lifting a heavy load even a short distance may require pulling a considerable length of chain through the system. However, for most applications, this is an acceptable compromise since human strength is limited, while time and distance are more flexible constraints.

Friction: The Inevitable Limiting Factor

1. Chain-on-Sheave Friction

As the load chain passes over the pulleys (sheaves), it experiences both sliding and rolling friction. The chain links must constantly bend and straighten as they engage and disengage with the sheaves, creating internal friction within the links themselves. Additionally, the contact points between the chain and the sheave groove create external friction, which is influenced by:

- Surface Finish:The smoothness of both the chain and sheave surfaces

- Material Compatibility:The interaction between the chain alloy and sheave material

- Lubrication State:The presence and condition of lubricating films

- Load Distribution:How the load is distributed across the contact area

2. Bearing Friction

Every rotating component—sheaves, gears, and the load spool—is mounted on bearings, which themselves generate friction. The type of bearing significantly impacts the friction coefficient:

| Bearing Type | Typical Friction Coefficient | Applications in Chain Hoists |

| Plain Bearings (Bushings) | 0.05 – 0.10 | Economy models, low-duty applications |

| Ball Bearings | 0.0015 – 0.003 | Standard duty hoists, moderate efficiency |

| Needle Roller Bearings | 0.002 – 0.004 | Compact designs, space-constrained applications |

| Tapered Roller Bearings | 0.002 – 0.006 | Heavy-duty hoists, high radial/axial loads |

3. Gear Mesh Friction

The teeth of interacting gears slide and roll against each other in a complex motion pattern. This engagement creates friction that is influenced by:

- Tooth Profile:Involute gear teeth are designed to minimize sliding friction

- Surface Hardness:Hardened gear surfaces resist wear and maintain proper meshing

- Lubrication:Proper gear lubrication is critical for separating mating surfaces

- Backlash:Excessive clearance increases impact forces and friction

4. Brake Mechanism Friction

Chain hoist brakes, whether mechanical, electrical, or hydraulic, rely on controlled friction for operation. This includes:

- Drag Friction:Minimal contact in disengaged state

- Engagement Friction:Controlled friction during braking action

- Static Friction:Friction that holds the load in position when stationary

5. Lubrication Condition

Proper lubrication is the single most important factor in controlling friction. The lubrication regime progresses through several stages:

| Lubrication State | Friction Coefficient | Characteristics |

| Boundary Lubrication | 0.05 – 0.15 | Thin film, high asperity contact, common at startup |

| Mixed Lubrication | 0.01 – 0.1 | Partial surface separation, moderate asperity contact |

| Full-Film Lubrication | 0.001 – 0.01 | Complete surface separation, lowest friction |

6. Load Magnitude and Distribution

Friction generally increases with load, but not always proportionally. The relationship follows the fundamental friction equation:

Frictional Force (F) = Coefficient of Friction (μ) × Normal Force (N)

However, at higher loads, lubrication films may thin out, increasing metal-to-metal contact and friction coefficients.

7. Operational Speed

Friction characteristics change with operational speed due to:

- Hydrodynamic Effects:Increased speed can improve lubricant film formation

- Inertial Forces:Higher speeds increase dynamic loads on components

- Temperature Effects:Friction-generated heat reduces lubricant viscosity

8. Environmental Conditions

External factors significantly impact friction performance:

- Temperature:Affects lubricant viscosity and material properties

- Contamination:Abrasive particles dramatically increase wear and friction

- Humidity:Can cause corrosion, altering surface characteristics

Types of Chain Hoists and Their Mechanical Configurations

Different types of chain hoists employ variations of the basic mechanical principles to achieve their lifting capabilities. The three main categories are differential, lever ratchet, and electric chain hoists, each with distinct mechanical configurations.

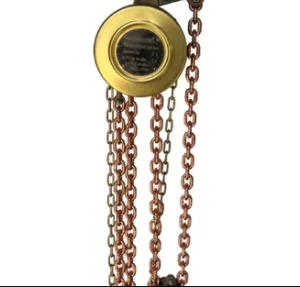

Differential chain hoists use an endless chain operating over two pulleys of slightly different diameters. The mechanical advantage comes from the difference in circumference between these pulleys. As the chain is pulled, it moves at different speeds over the two pulleys, creating a powerful lifting action with a relatively simple mechanism.

Lever ratchet hoists use a system of gears and a ratchet mechanism to provide mechanical advantage. The operator works a lever back and forth, with each stroke advancing the gear system slightly. These hoists offer the advantage of being operable in confined spaces and from various angles.

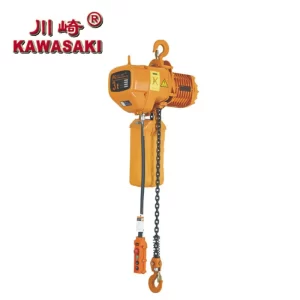

Electric chain hoists incorporate electric motors to provide the input force, but still rely on mechanical advantage principles in their gear and pulley systems to multiply the motor’s output. These systems can achieve very high mechanical advantages, allowing relatively small motors to lift extremely heavy loads.

Safety Considerations in Mechanical Advantage Systems

The force-multiplying capability of chain hoists that makes them so useful also introduces significant safety considerations. The high mechanical advantage means that any weakness in the system—whether in the hoist itself, the supporting structure, or the load attachment—can lead to catastrophic failure.

Perhaps the most critical safety aspect is that operators must never exceed the rated capacity of a hoist. The mechanical advantage system distributes forces in ways that may not be intuitively obvious, and overloading can cause sudden, dangerous failures. Regular inspection and maintenance are essential to ensure that all components remain in good working condition and can handle the forces for which they were designed.

Additionally, the mechanical advantage system means that if a load does fall, it will accelerate more rapidly than it would in free fall due to the multiple segments of chain and the pulley system. This makes proper securing of loads and use of safety hooks particularly important in chain hoist operations.

Conclusion: The Enduring Value of Simple Principles

The chain hoist stands as a testament to how fundamental physical principles, when properly applied, can dramatically extend human capabilities. The mechanical advantage achieved through pulley and gear systems transforms impossible lifting tasks into manageable operations across countless industries.

Understanding these principles not only satisfies intellectual curiosity but also promotes safer and more effective use of these powerful tools. From the ancient builders who erected monumental structures to modern technicians maintaining complex machinery, the mechanical advantage provided by chain hoists continues to be an indispensable technology—all thanks to the clever application of basic physics.

As technology advances, we may see improvements in materials, control systems, and efficiency, but the fundamental mechanical principles that allow chain hoists to lift heavy loads with minimal effort will remain unchanged. These timeless concepts continue to demonstrate that sometimes the most powerful solutions arise from understanding and working with nature’s basic rules rather than attempting to overcome them.