In busy warehouses or construction sites, chain hoists keep things moving. They lift heavy loads with ease, but one slip can lead to trouble. That’s why knowing the basics of safe operation matters so much. This post breaks down five key tips, drawn from years in the industry. We’ll touch on real-world examples, like how a simple check can save a day on the job.

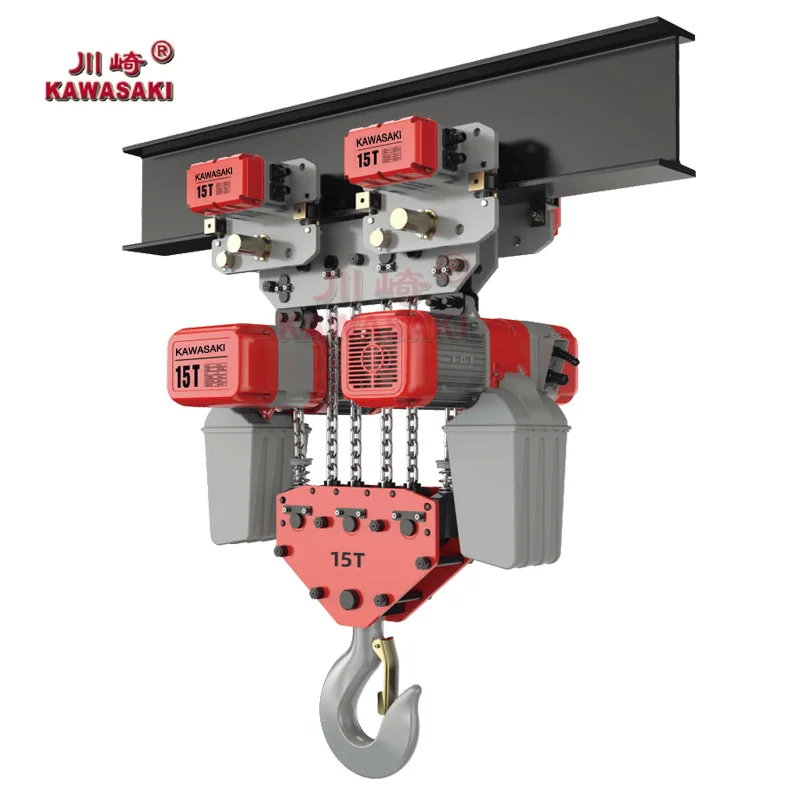

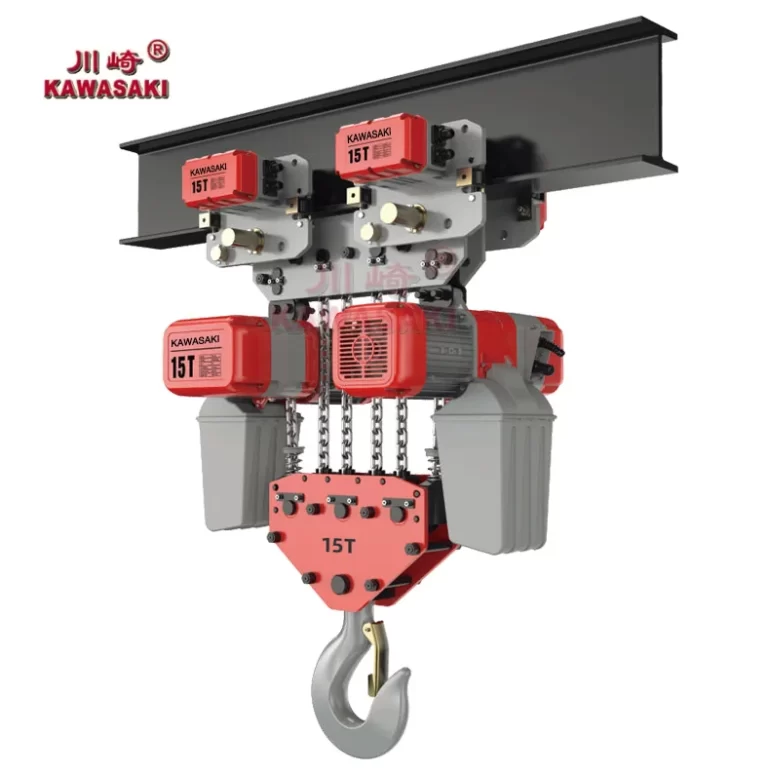

At Apollo Hoist, we’ve been building reliable lifting gear since 1986 as part of a Taiwanese family-run business under HSY International Group. Our Kawasaki brand focuses on quality products that last, with certifications like ISO 9001 and CE/GS to back them up. Let’s dive in and see how to handle these tools right.

Why Is Safety Crucial in Chain Hoist Operations

Safety isn’t just a buzzword in lifting work. It keeps people out of harm’s way and jobs running smooth.

Prevention of Workplace Accidents

Think about a factory floor where a chain hoist drops a 2-ton load because of a worn link. Accidents like that happen too often, leading to injuries or worse. According to industry reports, over 5,000 lifting-related mishaps occur yearly in the U.S. alone. Sticking to safety cuts those numbers down. For instance, in a Singapore warehouse we supply, regular checks dropped incident rates by 40%. It’s about spotting issues early.

Protection of Valuable Equipment

Chain hoists aren’t cheap. A damaged one from rough use can cost thousands to fix or replace. Proper handling extends their life. Our Kawasaki models, built with tough alloy steel, hold up well, but even they need care. Imagine leaving a hoist exposed to rain—rust sets in fast, shortening its span from 10 years to just a few.

Compliance with Industry Standards

Rules from OSHA or European CE guidelines aren’t optional. They set the bar for safe work. Falling short means fines or shutdowns. Apollo Hoist products meet these head-on, with GS safety marks on every unit. We’ve seen clients in Malaysia avoid hefty penalties by using certified gear. It pays off in the long run.

What Should You Inspect Before Using a Chain Hoist

Grab your checklist. A quick look-over before starting can catch problems that might turn ugly.

Chain and Hook Condition

Run your eyes and hands over the chain. Look for cracks, twists, or stretched links. Hooks should sit straight without bends. In one case, a construction crew in Thailand found a nick in the chain during inspection—swapped it out and avoided a collapse. Our Kawasaki chain hoists use T80 or T100 grade chains, customizable with galvanizing for extra toughness against wear.

Load Limit Labels

Those tags aren’t decoration. Check the working load limit (WLL) stamped on the hoist. It tells you the max it can handle safely. Mixing it up with a heavier load? Bad idea. We’ve supplied units rated up to 20 tons, like the CK 20T manual chain hoist, where clear labels make it easy to match the job.

Brake and Mechanism Functionality

Test the brakes. Pull the chain and see if it holds firm. Gears should turn without grinding. A faulty brake once caused a slow drop in an Indonesian plant, but quick testing caught it. Apollo’s electric models, such as the KKBB chain hoist, come with dual braking systems for that extra layer of reliability.

How Can You Prevent Overloading a Chain Hoist

Overloading is a common mistake. It strains everything and invites failure. Stay smart about weights.

Verify Load Weight Accurately

Weigh the load first. Use a crane scale like our OCS model, which displays clear LCD readouts up to tons. Guessing? That’s how a 1.5-ton hoist buckled under 2 tons in a Korean shipyard. Accurate scales prevent that mess.

Match Capacity to Task

Pick the right hoist for the job. A 1-ton unit for light warehouse picks, or bump to 10 tons for heavy industrial lifts. Our CK series offers options from 1T to 20T, with features like load limiting to stop overloads cold.

Utilize Overload Protection Features

Many hoists have built-in safeguards. Slip clutches or electronic limits kick in when things get too heavy. In our DCER normal operation electric chain hoist, overload protection is standard, helping operators in dusty or wet spots keep control without guesswork.

What Are Safe Practices for Lifting with Chain Hoists

Lifting isn’t just yanking a chain. Do it wrong, and loads swing wild.

Center Load Directly Underneath

Position the hoist straight above the load. Off-center pulls twist chains and tip things over. Picture a beam in a Japanese build site—centered right, it lifts clean; skewed, it sways and risks workers below.

Avoid Side Pulling Actions

Never drag loads sideways. It wears hooks and chains unevenly. Stick to vertical lifts. Our lever hoists handle angles better in tight spots, but even then, keep it minimal to avoid snaps.

Lift Slowly and Steadily

Rush it, and shocks stress the system. Start slow, build speed if needed. In family garages or big plants, steady lifts mean fewer jerks. Apollo’s two-speed electric hoists, like the LES wire rope model, let you control pace for safer handling.

Why Must Operators Receive Proper Training

No one should grab a hoist without know-how. Training turns rookies into pros.

Understand Hoist Operations

Learn the controls inside out. From manual pulls to electric buttons, get the feel. We’ve provided video guides for clients in South Korea, showing step-by-step on models like the KKBB, cutting learning curves short.

Identify Potential Hazards

Spot dangers like frayed wires or unstable ground. Trained eyes catch them early. In one Thai factory, operators flagged a loose bolt during a drill—averted a big issue.

Follow Emergency Protocols

Know what to do if something jams. Lower loads safe, call for help. Our after-sales include one-year warranties and accessory support, plus tips on quick fixes to keep things moving.

How to Maintain Chain Hoists for Long-Term Safety

Keep your hoist in shape. A little upkeep goes far.

Perform Regular Cleaning

Wipe off grime after use. Dust and grease build up, jamming parts. Use mild soap on chains; avoid harsh stuff that eats metal. Clients in humid Indonesia swear by this for rust-free gear.

Schedule Routine Inspections

Check monthly or after heavy jobs. Look at wear on hooks, test brakes. Our ISO-certified process ensures every Kawasaki unit leaves the factory tested, but field checks keep them prime.

Ensure Proper Storage

Hang them dry, away from elements. Coiled chains prevent kinks. In our Taiwan base, we store prototypes this way, lasting decades. Simple habits like this extend life.

How Can Apollo’s Kawasaki Products Boost Safety

Apollo Hoist stands out with customizable, tough gear. Tailored for your needs, from explosion-proof to rain-resistant.

Dual Braking in KKBB Model

The KKBB electric chain hoist packs dual brakes for fail-safe stops. Ideal for high-risk spots, it holds loads even if one brake slips. We’ve shipped 500 units monthly, helping factories run safer.

Limit Switches in DCER Hoist

DCER‘s limit switches prevent over-travel, stopping lifts at set points. No more banging into ceilings. It’s built for normal ops but handles custom voltages from 110V to 575V.

Custom Safety Features in LES Hoist

The LES wire rope hoist offers extras like frequency conversion for smooth speeds. Customize chains, colors, even packaging—MOQ starts at 50. Explosion-proof options suit harsh sites. As an OEM supplier with agents across Asia, we make safety fit your setup.

FAQs

Q1: What is the maximum load for a Kawasaki chain hoist?

A: It varies by model—our CK series goes from 1 ton up to 20 tons. Always check the label for your specific unit.

Q2: How often should I inspect my chain hoist?

A: Aim for daily quick checks and full inspections monthly, or after tough jobs. Follow your local regs for best practice.

Q3: Can I customize a hoist for outdoor use?

A: Yes, we offer rain-proof and dust-proof options on models like the KKBB or LES. Just specify when ordering, with a minimum of 50 units.