Introduction

Chain hoists are fundamental components in industrial lifting and material handling systems. They are widely used across manufacturing, warehousing, construction, mining, and logistics industries. Supplied by hoist manufacturers, hoist suppliers, and chain hoist manufacturers, these devices are designed to lift, lower, and position loads safely and efficiently.

Among the various configurations available on the market, single-chain hoists and double-chain hoists are two of the most common options. Selecting between them is not simply a matter of capacity; it involves considerations related to load stability, operating environment, crane integration, and long-term operational efficiency. This article explains the core differences between single-chain hoists and double-chain hoists and provides guidance for choosing the appropriate solution in industrial applications.

Overview of Chain Hoist Technology

Chain hoists operate by using a load chain that passes over a lifting wheel to raise or lower loads. They can be powered manually or electrically and are commonly integrated with crane systems supplied by crane manufacturers and crane suppliers. Electric chain hoists, in particular, are widely adopted due to their efficiency, consistency, and ease of control.

Chain hoists are often used alongside other lifting equipment such as industrial lifting clamps, magnetic lifters, hand winches, and electric winches, all of which are supplied by specialized lifting clamp manufacturers, magnetic lifter suppliers, hand winch manufacturers, and electric winch suppliers.

What Is a Single-Chain Hoist?

A single-chain hoist uses one load chain to support and lift the load. This is the most common configuration found in light- to medium-duty lifting operations and is widely produced by electric chain hoist manufacturers and manual hoist suppliers.

Structural Characteristics

Single-chain hoists feature a compact and lightweight structure. The load is supported by a single chain strand, which makes the hoist smaller in size and easier to install in environments with limited space.

Key characteristics include:

- One load-bearing chain

- Compact hoist body

- Lower overall weight

- Simplified mechanical structure

Because of these advantages, single-chain hoists are commonly used in industrial manual hoists, warehouse overhead crane systems, and small crane installations.

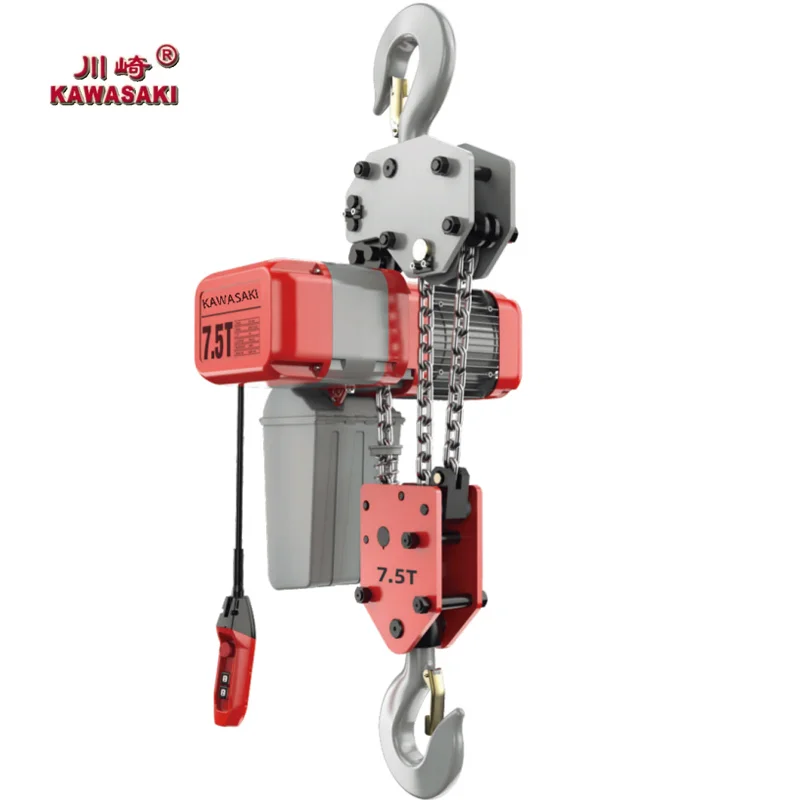

What Is a Double-Chain Hoist?

A double-chain hoist uses two parallel load chains to lift the load. This design distributes the load more evenly and reduces stress on each individual chain strand. Double-chain hoists are typically supplied by heavy lifting hoist suppliers and hoist manufacturers and suppliers that focus on high-capacity and high-duty lifting solutions.

Structural Characteristics

Compared with single-chain hoists, double-chain hoists are larger and heavier. They require more installation space and stronger supporting structures but offer improved performance in demanding applications.

Typical features include:

- Two synchronized load chains

- Enhanced load balance

- Reduced wear on chains and lifting components

- Increased structural rigidity

Double-chain hoists are frequently integrated into industrial lifting crane systems designed by industrial crane manufacturers and overhead crane manufacturers.

Load Capacity and Lifting Capability

Single-Chain Hoist Capacity

Single-chain hoists are best suited for lower-rated capacities. They are commonly used in environments where loads are moderate and handling speed is a priority. Typical applications include:

- Assembly lines

- Maintenance workshops

- Machine shops using machine shop cranes

- Warehouses utilizing crane for warehouse solutions

Many electric chain hoist suppliers offer single-chain models due to their versatility and cost efficiency.

Double-Chain Hoist Capacity

Double-chain hoists are designed for higher load capacities and are often selected for heavy-duty operations. They are widely used in industries such as:

- Steel fabrication

- Shipbuilding

- Mining operations requiring electric hoist for mining operations

- Large construction projects involving crane used in construction

In some cases, double-chain hoists are used alongside products from electric wire rope hoist manufacturers to handle extremely heavy or tall lifting requirements.

Load Stability and Safety Considerations

Stability in Single-Chain Hoists

Single-chain hoists perform well when lifting centered and symmetrical loads. However, off-center loads can introduce load swing or twisting. To improve safety, they are often combined with industrial lifting clamps or accessories from lifting clamp manufacturers.

Single-chain hoists are commonly used in environments where load control requirements are moderate and operational simplicity is valued.

Stability in Double-Chain Hoists

Double-chain hoists offer superior load stability due to their dual-chain configuration. The load is distributed evenly, significantly reducing sway and improving positioning accuracy. This makes them suitable for:

- Automotive manufacturing lines supported by car hoist manufacturer solutions

- Precision industrial assembly

- Heavy equipment handling

Because of their stability, double-chain hoists are often recommended by leading crane manufacturers and crane hoist manufacturers.

Installation Requirements and Space Constraints

Single-Chain Hoist Installation

Single-chain hoists require less headroom and structural support, making them ideal for retrofitting existing facilities. They are commonly installed on:

- Warehouse overhead crane systems

- Monorails and jib cranes

- Small cranes from small cranes manufacturers

Their compact size also simplifies integration with crane parts suppliers’ components.

Double-Chain Hoist Installation

Double-chain hoists require more space and stronger crane structures. They are commonly installed on:

- Heavy-duty overhead cranes

- Gantry cranes

- Port and shipyard cranes supplied by port crane manufacturers and large crane manufacturers

These hoists are frequently selected for industrial lifting crane systems operating under high-duty classifications.

Lifting Speed and Duty Cycle

Lifting speed and duty cycle are critical performance parameters when evaluating single-chain hoists and double-chain hoists. These factors directly influence operational efficiency, equipment lifespan, and suitability for specific industrial applications. Understanding how each hoist configuration performs under different operating conditions helps end users select the most appropriate solution for their lifting requirements.

Lifting Speed Characteristics

Single-chain hoists are generally designed to deliver higher lifting speeds, particularly when handling lighter loads. Because the load is supported by a single chain strand, the mechanical system experiences lower resistance, allowing the motor or manual drive to operate more efficiently. This makes single-chain hoists well suited for applications that require frequent lifting, short cycle times, and rapid material handling, such as assembly lines, maintenance tasks, and warehouse operations.

In contrast, double-chain hoists often operate at comparatively lower lifting speeds. The presence of two load chains increases mechanical load and system complexity, which can slightly reduce lifting speed. However, this design trade-off is intentional, as double-chain hoists prioritize load stability, safety, and controlled movement over speed. In heavy-duty environments, slower and more controlled lifting is often preferred to minimize dynamic forces and enhance operator safety.

Duty Cycle and Operational Intensity

Duty cycle refers to the amount of time a hoist can operate within a given period without overheating or experiencing excessive wear. Single-chain hoists are typically rated for light to medium duty cycles. They perform efficiently in applications where lifting operations are intermittent and loads remain within moderate weight ranges. For facilities with predictable lifting patterns and limited continuous operation, single-chain hoists offer an effective balance between performance and cost.

Double-chain hoists are engineered for higher duty classifications and continuous operation. The dual-chain configuration distributes the load more evenly, reducing stress on individual components such as chains, gears, and motors. This design allows double-chain hoists to operate for longer periods under heavy loads without compromising reliability. As a result, they are commonly used in high-intensity industrial environments, including steel processing, mining, shipbuilding, and large-scale construction projects.

Impact on Efficiency and Equipment Longevity

From an efficiency standpoint, selecting the correct hoist type based on lifting speed and duty cycle can significantly reduce downtime and maintenance costs. Single-chain hoists provide excellent efficiency in high-speed, low-load scenarios, while double-chain hoists excel in maintaining performance consistency under sustained heavy lifting.

Over time, operating a hoist beyond its intended duty cycle can lead to premature wear, increased maintenance requirements, and safety risks. Therefore, matching the hoist configuration to the actual operating conditions is essential for maximizing service life and ensuring compliance with industrial safety standards.

Application-Based Selection Guidance

For operations that prioritize speed, frequent starts and stops, and lighter loads, single-chain hoists are typically the preferred solution. For applications involving heavy loads, long operating hours, or demanding environmental conditions, double-chain hoists offer superior durability and operational stability.

By carefully evaluating lifting speed requirements and duty cycle demands, end users can ensure that the selected hoist not only meets immediate operational needs but also delivers reliable long-term performance within the overall lifting system.

Integration with Cranes and Winches

Chain hoists are integral components of many crane systems. Both single-chain and double-chain hoists are used in:

- Crane used in industry

- Warehouse crane types

- Types of crane in industry such as overhead, gantry, and jib cranes

Double-chain hoists are more commonly found in high-capacity crane hoist supplier systems.

Chain hoists also operate alongside winches, including industrial hand winch products, hand winch suppliers’ offerings, and electric winch systems. These combinations provide flexible lifting and pulling solutions in complex industrial environments.

Industry Applications

Manufacturing and Warehousing

In manufacturing and warehousing, single-chain hoists are widely used due to their affordability and ease of operation. They are ideal for facilities using crane for warehouse layouts and machine shop cranes.

Construction and Infrastructure

Construction projects often require higher lifting capacity and enhanced stability. Double-chain hoists are commonly used in conjunction with construction crane for sale systems, loader cranes from loader crane manufacturers, and mobile cranes.

Mining and Heavy Industry

Mining and heavy industrial environments demand robust and reliable lifting equipment. Double-chain hoists supplied by electric hoist manufacturers and hoist lift manufacturers are frequently chosen for their strength and safety margins.

Cost, Maintenance, and Lifecycle Considerations

Single-chain hoists typically have lower initial costs and simpler maintenance requirements. They are a practical choice for operations working with budget constraints and supported by manual hoist suppliers or standard hoist suppliers.

Double-chain hoists involve higher upfront investment but offer longer service life under heavy loads. For heavy lifting solutions, the reduced wear and increased safety often justify the higher cost over the equipment lifecycle.

How to Choose the Right Chain Hoist

When selecting between a single-chain hoist and a double-chain hoist, buyers should evaluate:

- Rated load and safety requirements

- Operating frequency and duty cycle

- Available installation space

- Integration with cranes, winches, and accessories

- Technical support from hoist manufacturers and suppliers

Consulting experienced hoist manufacturers, crane hoist manufacturers, and crane suppliers ensures compliance with safety standards and optimal system performance.

Conclusion

Single-chain hoists and double-chain hoists each play an important role in modern industrial lifting systems. Single-chain hoists provide compact design, flexibility, and cost efficiency for light to medium loads. Double-chain hoists deliver superior load stability, higher capacity, and durability for demanding applications.

By understanding these differences and working closely with trusted hoist manufacturers, electric chain hoist suppliers, and industrial crane manufacturers, businesses can implement safer, more efficient lifting systems that support long-term operational success across a wide range of industries.