Hand winches play a steady role in lifting, pulling, and positioning loads in workshops, farms, construction sites, and industrial settings. A lot of users tend to focus on capacity labels alone, but the real foundation of safe operation lies in knowing the Safe Working Load (SWL) and how it is calculated. A clear calculation method helps prevent overload and also gives users confidence in long-term use. With Apollo’s KAWASAKI manual winches, this calculation becomes more reliable because the products are built with stable braking parts, sealed gearboxes, and long-life materials.

What Factors Influence the Safe Working Load of a Hand Winch?

Before going into formulas and steps, it’s helpful to understand the elements that shape the final SWL value. These factors affect how much force the winch can handle without slipping, deforming, or putting the operator at risk.

Load Characteristics and Material Behavior

Different loads behave differently when pulled or lifted. A compact steel block reacts in a more predictable way compared with bulky or irregular shapes. Materials with shifting centers of gravity or slippery surfaces might need additional safety margins. Winch designers usually consider these variables when building gears, ratchets, and braking shoes. For Apollo’s KAWASAKI winches, the internal materials are tested according to ISO9001 quality checks, which helps keep the actual load performance close to the rated numbers.

Winch Structure and Mechanical Components

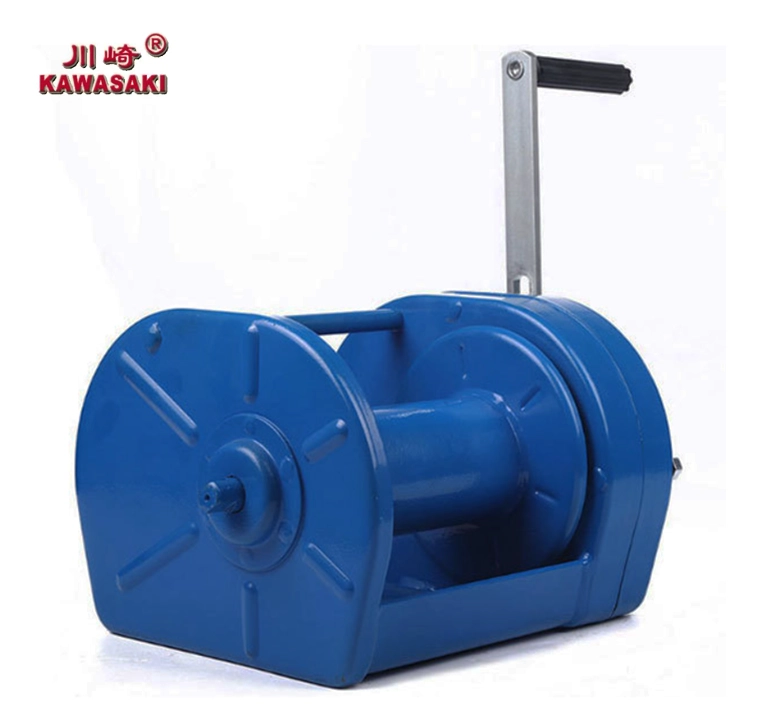

The internal structure—gear thickness, housing strength, brake pawl design, and handle mechanism—directly shapes the SWL. A larger ratchet drum can store more rope and distribute force over a wider contact area. A reinforced gearbox casing keeps the teeth from flexing during heavy tasks. Apollo’s KAWASAKI HAND WINCH GPW uses a sealed gearbox and an updated brake pawl, helping the core parts stay steady even after long-term friction. Apollo’s JC-E model also has a compact but tough mechanical frame suitable for routine use in small industrial environments.

Rope Selection and Strength Ratings

The rope often becomes the weakest part of a lifting system, so its type matters. Steel wire rope, synthetic rope, and mixed-core lines all have different tensile strengths. When rope diameter decreases or wears out, its load capacity drops fast. Winches from Apollo allow users to select different rope materials depending on the site environment, giving some flexibility without sacrificing safety.

How to Determine the Working Load Limit Step by Step?

Once the factors are clear, the next step is applying a basic calculation method. These steps break the process into simple actions, so the operator can check the numbers without complex engineering tools.

Safety Factor Application and Industry Standards

Industrial applications usually use a safety factor between 4:1 and 5:1. This means if a rope breaks at 2,000 kg, the SWL might be set around 400–500 kg. The factor accounts for wear, temperature, shock load, and operator habits. Apollo’s internal testing process, which includes load checks and assembly inspections, helps the product meet CE and GS certification requirements. These certifications follow common global safety margins, so they match what most industries prefer.

Verification Through Practical Load Testing

Even a correct calculation benefits from practical checks. Load testing confirms that the winch does not slip under weight, and the brake engages smoothly without sudden drops. The sealed braking system on the KAWASAKI GPW keeps dust and debris out, which is useful in areas with sand, concrete powder, or metal shavings. The JC-E model also performs steadily during repetitive low-speed jobs because of its reliable mechanical clutch and internal gear design.

Why Should You Choose Apollo Hand Winches for Accurate SWL Control?

After understanding how SWL is calculated, many users look for equipment that can keep actual performance close to the calculated number. This is where Apollo’s manual winches stand out.

High-Strength Gearbox and Enclosed Brake System

The GPW model uses a fully enclosed gearbox, a design that keeps dirt from getting inside. This approach reduces internal wear and keeps brake response more consistent. When the inner gears stay clean and in place, the winch behaves more predictably when lifting close to its working limit.

Enhanced Stability with Dual-Purpose Handle Design

Some winches can only rotate in full circles, which can be tricky in tight spaces. The GPW’s lever handle works in both full-circle rotation and back-and-forth swinging, letting the operator work even when obstacles are close. This practical handle design makes load control smoother, especially when fine adjustments are needed.

Durable Structure with Sealed Mechanism for Long-Term Accuracy

The JC-E manual winch is compact, but its frame, drum, and internal mechanism are built from sturdy alloy steel. Routine pulling tasks—like maintenance lifting, workshop positioning, or basic construction work—stay stable because the internal friction surfaces don’t degrade as quickly. This stability helps keep SWL performance close to factory ratings over the product’s lifespan.

How Do Environment and Usage Conditions Affect SWL?

Real-world conditions can change the load capacity of any winch system. Considering these site factors early helps prevent sudden performance drops during operation.

Temperature, Humidity, and Corrosion Exposure

Cold temperatures can make metal slightly more brittle, while heat may soften brake pads. Moisture brings rust, especially on untreated parts or exposed rope sections. Apollo’s sealed components and weather-resistant materials help reduce these risks, though regular checks remain important.

Frequency of Operation and Duty Cycle

A winch used once a week behaves differently from one used all day. Continuous work brings heat and friction, which slowly reduce braking strength. Apollo’s manual winches are built for repeated operation, but every unit still benefits from resting intervals during long shifts.

Installation Angle, Mounting Surface, and Rope Path

The angle of pull can shift load force. A straight pull provides the best efficiency, while diagonal angles can increase side stress. A solid mounting surface also helps keep the frame from twisting. KAWASAKI winches can work in various directions, but planning the rope route gives more accurate SWL performance on the job.

How Can You Maintain Your Winch to Keep SWL Stable Over Time?

Maintenance plays a key role in keeping a stable and predictable SWL. A few simple habits are enough to keep the winch from drifting away from its rated capacity.

Routine Inspection and Lubrication Practices

Light lubrication on the gears and handle joints keeps the winch moving smoothly. Checking the ratchet teeth for chips or visible wear also helps catch problems early. The GPW’s enclosed design makes these inspections easier because fewer contaminants enter the housing.

Brake and Gearbox Stability Checks

A brake that feels uneven, sticky, or too loose needs attention. Brake pads on manual winches slowly wear down, and dust can build up on friction plates. Because Apollo uses sealed braking parts, the cleaning intervals are longer, but checking the brake action before heavy work remains a good habit.

Rope Condition Monitoring and Replacement Cycle

Rope strands should be replaced when fraying, flattening, or rusting appears. Even high-strength ropes lose capacity after months of friction. Users often mark rope inspection dates on a simple tag to keep track—a small habit that helps maintain SWL accuracy without any special tools.

FAQ

Q1: How often should a hand winch be load-tested?

A: Most industrial users test once every 6–12 months, while heavy-use environments may perform checks more frequently.

Q2: Can synthetic rope be used with KAWASAKI hand winches?

A: Yes. Both GPW and JC-E models can work with different rope materials, as long as the rope matches the breaking strength required for the job.

Q3: What is the biggest advantage of Apollo’s sealed brake design?

A: It protects the braking parts from dust and debris, helping the winch keep stable load control even in rough or dirty environments.