In the world market for handling materials, China has turned into a main provider for cranes, hoists, and other lifting tools. Buyers from building, shipping, and making sectors often go to Chinese plants for dependable and cheap lifting items. But with lots of choices out there, knowing what to check before buying is very important. The right seller can mean the difference between easy work and sudden stops.

Hangzhou Apollo Hoist — part of HSY International Group — has been a trusted name in lifting machinery since 1986. Its “KAWASAKI” brand is well-known in Asia and other places for giving good performance, fair prices, and custom OEM/ODM options. Here’s what every buyer from abroad should look at before getting lifting equipment from China, and why Apollo is special in this area.

Why Is It Important to Choose the Right Lifting Equipment Supplier?

Picking a good lifting equipment seller is not just about the cost. It is also about steady products, official papers, and helpful service. Many Chinese makers can supply electric or hand hoists. But not all of them follow tight rules for quality and safety.

Manufacturer Reputation and Certification

A good name says more than any list of items. Apollo has more than thirty years of making experience. It holds ISO9001 and CE/GS safety certifications. These papers show that the company sticks to strict quality rules and European safety rules. Started in Taiwan and then grew to Japan and mainland China, Apollo mixes Asian skills with world research power.

Quality Management and Inspection System

Every hoist that leaves Apollo’s plant gets careful checks. There is a full check of the whole machine to make sure all parts fit and work right. The plant also does tests on how it works. This includes load tests, balance checks, and safety reviews. This way helps make sure that each electric or chain hoist works the same in real jobs.

Global Service Network and OEM Capability

Apollo does not just sell items — it makes friends with buyers. With sellers in Japan, Singapore, Malaysia, Thailand, and South Korea, the brand has a strong spot around the world. Besides its own items, Apollo gives OEM/ODM changes. This helps other brands make lifting tools with their own name, special looks, boxes, and details.

How to Evaluate Product Quality Before Purchase?

Even with trusted sellers, buyers still need to know what makes a good lifting tool. The right check can stop many problems later. This is true for long use in factories.

Material and Structural Strength

Good stuff makes the biggest change. Apollo’s hoists use strong alloy steel and parts that last against wear. This gives them the toughness to deal with hard jobs. Whether in a building area or storage place, this build makes sure of steady work and longer use.

Safety Features and Performance Testing

New lifting items must meet tight safety rules. Apollo adds many guard systems — like overload stops, auto shut-off, dust-proof and explosion-proof builds — to make work safer. Each unit gets tested for lift speed, balance, and steadiness before it ships.

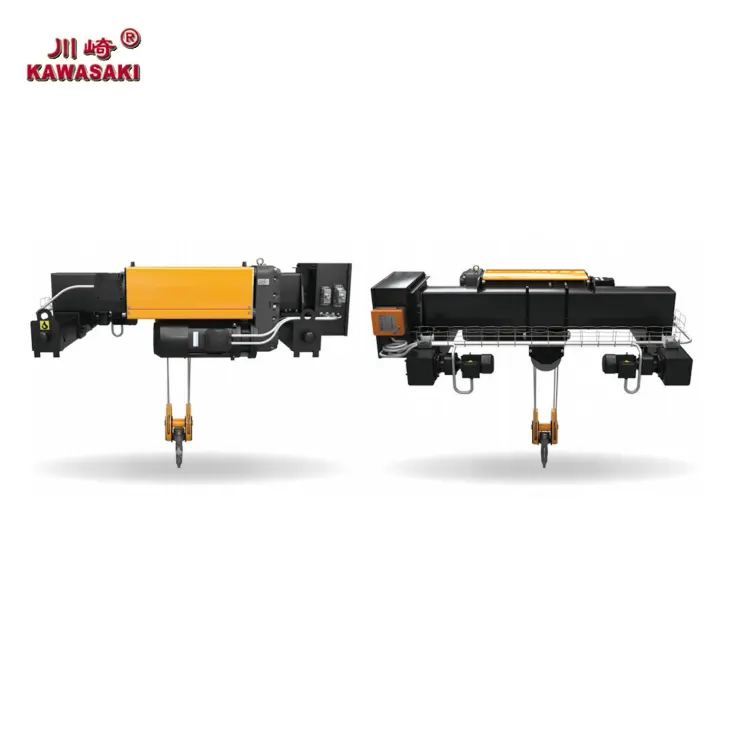

Example: KAWASAKI European Type Wire Rope Electric Hoist DHX

For buyers who want exact and strong lifts, the KAWASAKI European Type Wire Rope Electric Hoist DHX is one of Apollo’s top models. Made under European rules, it gives steady lift power and easy moves with small build. It fits lines for making, ship areas, and fix shops that need exact and dependable work.

What Customization Options Are Available for Overseas Buyers?

Many buyers from other countries have special power systems, names, or place needs. This is where Apollo’s change skills become a real help.

Functional Customization

Apollo gives many choice functions — from explosion-proof and rain-proof kinds to models with speed control or two-speed lifts. These choices let buyers change hoists for special work spots. This includes chemical plants or outside jobs.

Appearance and Branding Customization

For sellers and own brands, looks matter a lot. Apollo can change color, sign, and boxes. This helps each friend keep a same brand look. This bend is one reason many companies from abroad pick Apollo for long OEM work.

Voltage and Material Customization

Different places use different power. Apollo works with single-phase or three-phase power from 110V to 575V. Chain stuff can also get changed — from T80 to T100 grades — based on the load and work spot.

Which Types of Electric Hoists Fit Different Industrial Needs?

Not all lift jobs are alike. A storage place does not need the same setup as a build site or making line. Apollo’s electric hoist kinds cover many factory scenes.

KAWASAKI Hook Type Electric Chain Hoist DCEK

The DCEK series is known for its light body and easy move. It is great for small plants, work areas, or storage spots where room is tight but lifts happen often. The hook build makes setup fast and bendy.

KAWASAKI Normal Operation Electric Chain Hoist KKBB

For heavier use or long hours, the KKBB model is top. It works for steady runs, even lifts, and comes with choices for dust-proof and explosion-proof setups. It is made for hard spots like steel plants and put-together lines.

KAWASAKI European Type Wire Rope Electric Hoist DHX

The DHX is best for high-exact and big-load lift tasks. It is often used in factory making or ship fixes where exact and smooth control is key.

How to Compare Apollo with Other Chinese Manufacturers?

With hundreds of hoist makers in China, it is easy to lose track in item lists. But checking main things like item kinds, quality, and help after buy helps pick fewer.

Broader Product Range and ODM/ OEM Services

While some rivals like TOHO or TXK stick to certain item types, Apollo gives a full list — from electric and hand hoists to winches, jacks, trolleys, and lifting clamps. Its ODM/ OEM service is another big good, giving buyers freedom to make changed items under their own name.

Higher Production Capacity and Quality Control

Apollo keeps a monthly make of 5,000 chain hoists and 500 electric hoists. This is backed by a good supply line. Every item goes through ruled put-together and checks. This helps keep same quality in big buys.

International Presence and Long-Term Reliability

The company’s links across Singapore, Japan, Malaysia, and Thailand show its dependability. Many buyers from abroad like Apollo because it gives steady talk, ready boxes for send, and a shown record of safe work around the world.

What After-Sales Support Should Buyers Expect?

Good help after buy is what keeps factory items running well after get. Apollo sees this as a must part of the buy time.

Comprehensive Warranty and Spare Parts Supply

All KAWASAKI hoists come with a one-year warranty. Swap parts are ready for long fix. This cuts the fear of stops and extra money later.

Technical Guidance and Training Videos

Apollo gives video lessons and use help. This makes it easier for end users or sellers to get the right use of each model. For clients from abroad, this kind of far help is very useful.

Marketing Assistance for Distributors

For B2B sellers, Apollo can give ad books and sell stuff. This helps re-sellers show the brand better to their own buyers.

Why Is Apollo a Trusted Choice for Global Buyers?

After almost forty years in the field, Apollo has won its spot among top lifting equipment senders in Asia. From Taiwan to Japan to Hangzhou, its growth comes from new ideas and buyer trust.

Proven History and Engineering Expertise

Started in 1986, Apollo’s deep know in lift tech is backed by a research center in Osaka, Japan, set in 2001. This gives the company both the make power of China and the exact build rules of Japan.

Consistent Product Quality with International Standards

Every KAWASAKI hoist — whether electric or manual — is made under tight quality rule. It meets ISO and CE certifications. These rules have made Apollo a steady seller for fields that like both work and safety.

Reliable OEM/ODM Partner for Long-Term Cooperation

Apollo’s skill to change items for different areas and clients makes it a long friend for world bringers. Whether a buyer needs a changed hoist color, special power, or new box style, the company gives bendy, quick, and dependable help.

FAQs

Q1: What’s the minimum order quantity for Apollo’s electric hoists?

A: Apollo’s standard minimum order quantity is 50 units for electric hoists and 100 units for manual hoists, but this can be discussed depending on the customization level.

Q2: Does Apollo support small-batch OEM or sample orders?

A: Yes. Apollo often provides sample units for quality inspection before mass production. OEM cooperation for small batches is also available.

Q3: How long does it take to produce and ship an order?

A: Production typically takes 30 to 45 days, depending on the model and quantity. Apollo offers export-standard packaging (paper cartons or wooden boxes) for safe long-distance shipment.