In plenty of industrial spots, lifting stuff is just another part of the daily grind. Think about steel coils, machine bits, frames, and ready-made goods—they all have to shift from spot to spot. But when things get really heavy and you need to hoist them way up high, old-school hand tools just don’t cut it anymore. That’s when an electric wire rope hoist steps in as a solid, go-to option.

You see these hoists all over factories, processing setups, and shipping hubs. Folks love them for their steady pulls, smooth handling, and how they last through tough shifts. At Apollo, we supply lifting gear under the KAWASAKI brand, and we zero in on those real-world demands. Our roots are in Taiwan for building, with Japanese tech backing us up. We craft hoists that handle actual job sites, not just look good on paper. Getting a handle on how they tick helps folks pick the right setup for their loads, heights, and work rhythm.

What Is an Electric Wire Rope Hoist?

Before diving into motors or buttons, it’s smart to grasp what job a wire rope hoist does in a busy plant. This gear shines when you’re dealing with big weights, tall lifts, and the need for rock-solid steadiness all at once.

Definition of an Electric Wire Rope Hoist

Simply put, an electric wire rope hoist is a powered gadget that hauls loads up and down with a tough steel wire rope coiled around a spinning drum. An electric motor drives it all, and you control it via a handy pendant or panel. Unlike chain hoists, these are great for longer hauls or chunkier loads.

Most times, they’re hooked up to overhead cranes, gantry setups, or sturdy beams. Once in place, they chug along shift after shift. In many shops, they’re running non-stop for hours. So, dependability beats out flashy extras every time.

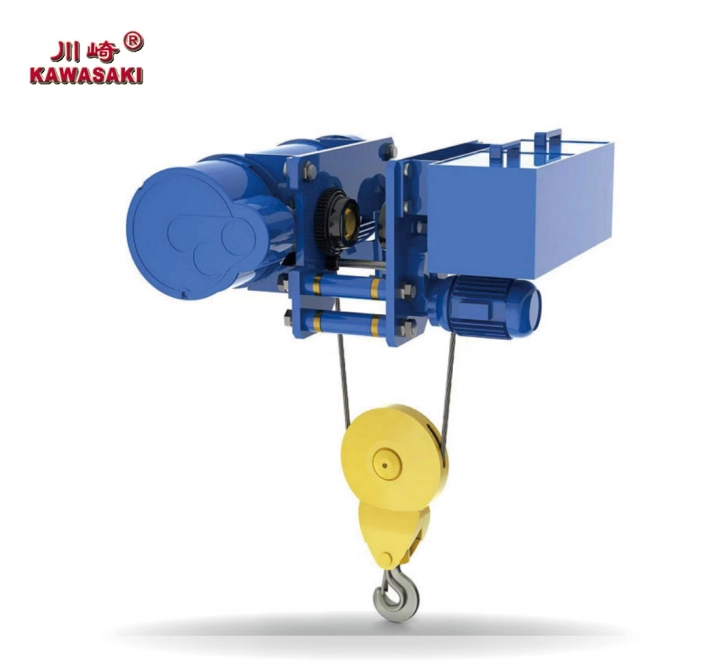

Main Parts and Overall Structure

Each electric wire rope hoist has a straightforward setup. The motor cranks out the power to lift. Then there’s a gearbox that slows things down but amps up the torque. The drum wraps and unwraps the wire rope neatly. At the end, a hook block grabs the load. Brakes lock everything tight when you pause. And limit switches keep things from going too far.

Sure, the basic layout is the same industry-wide, but it’s the build quality that sets them apart. Sloppy fits or cheap materials mean shakes, rattles, and quick breakdowns. Our KAWASAKI wire rope hoists pay close attention to those key spots, like the drum and gears, where pressure builds up the most.

Typical Industrial Applications

These hoists pop up everywhere—from steel shops and machine builders to power stations, storage yards, and coating lines. They’re perfect where you need smooth lifts and spot-on placement. For long distances or back-to-back hauls, wire rope models often outpace chain ones.

How Does a Rope Electric Hoist Work?

You know what it is, but how exactly does it manage to hoist those massive loads without a hitch? The basics are straightforward, yet the fine points make all the difference on the job.

Basic Operating Principle

Hit the button on your controller, and juice flows to the motor. It spins up right away. That spin goes through the gearbox, which dials back the speed but cranks up the muscle. Then the drum turns, pulling or letting out the wire rope. Rope winds in? Load goes up. Rope pays out? Load comes down nice and easy.

The real trick is keeping it controlled. Starts should feel gentle, and stops shouldn’t jolt. Solid teamwork between the motor, gears, and brakes makes every move predictable, no matter the weight.

Interaction Between Core Components

The motor isn’t flying solo here. The gearbox shifts power smoothly. And the drum’s grooves keep the rope straight and even, avoiding bunches or quick wear. Over time, that setup stretches the rope’s life and keeps lifts steady.

With KAWASAKI wire rope hoists, we spread out the strain so no part gets overworked. Instead of maxing everything out, we balance the load. That cuts down on heat, shakes, and wear that builds up over months.

Safety Devices and Control Functions

Safety’s baked right in with today’s hoists. Switches up top and down low halt things before anything bangs or breaks. Brakes grip firm if power dips out. Plus, overload guards stop risky tries.

In fast-paced shops, these bits are just routine. They shield the gear, sure, but more importantly, they keep workers and nearby kit safe.

Why Choose Apollo’s Electric Wire Rope Hoist Solutions?

With so many hoist makers out there, smart buyers dig deeper than specs. Things like track record, steady quality, and backup service make a huge difference for the long haul.

Manufacturing Experience and Quality Control

Apollo Hoist comes from a family-run outfit in Taiwan that kicked off back in 1986. We run our KAWASAKI brand with an R&D spot in Osaka, Japan. That setup lets us keep improving and watch every build step closely.

Our gear meets top safety rules worldwide. Every unit gets a full test before it ships out. That cuts way down on surprises once it’s up and running at your place.

Customization for Different Working Sites

No two sites are alike, right? Power setups vary by country. Some spots are dusty or steamy. Others deal with acids or high temps. That’s why we offer OEM and ODM tweaks—adjusting speed, voltage, coatings, and seals to fit your needs.

This way, the hoist matches your work, not the other way around. In the end, it means less downtime and simpler fixes.

After-Sales Support and Supply Network

A hoist sticks around for years, so parts, tips, and help are key. We team up with agents and partners in lots of areas. That covers quick parts delivery, how-to advice, and upkeep support. It’s all about keeping your setup humming, not gathering dust.

What Types of Electric Wire Rope Hoists Does Apollo Offer?

Different fields throw different challenges at lifting gear. Our KAWASAKI lineup covers that with models built for specific tough spots.

KAWASAKI Ultrahigh Type Steel Wire Rope Electric Hoist

This one’s a beast for heavy-duty jobs. It’s ideal for plants where big loads get hoisted over and over all day. Steel mills, assembly lines, and big fab shops pick it often.

Its tough build handles high cycles and keeps things stable. If steady runs and long life are your priorities, this model’s a smart pick.

KAWASAKI Square Box Type Pickling and Galvanizing Steel Wire Rope Electric Hoist

Pickling and galvanizing spots are rough—think damp air, acid fumes, and rust eating away fast. The KAWASAKI Square Box Type Pickling and Galvanizing Steel Wire Rope Electric Hoist is made tough for that.

Its sealed design and special coatings guard the insides. Perfect for coating lines where a breakdown means halted work and safety headaches.

KAWASAKI Low Static Air Type Wire Rope Electric Hoist

In stuffy workshops with dust everywhere or poor airflow, static and particles can mess with electrics and parts. The KAWASAKI Low Static Air Type Wire Rope Electric Hoist tackles that head-on.

It’s great for tight spaces or dusty zones. The setup keeps it running smooth even when conditions aren’t perfect.

How to Select the Right Electric Wire Rope Hoist

Picking the best hoist isn’t just about checking weight limits. You gotta weigh a bunch of real-life factors side by side.

Load Capacity, Lift Height, and Usage Frequency

Kick off with your actual loads, not just the max. Think about how often you hoist per shift and how far up you go. For constant use, go for higher-duty models—they hold up better over time.

Environmental Conditions

Heat, moisture, grit, and chemicals all take a toll. A hoist built for harsh setups usually runs smoother than a basic one shoved into the same spot.

Control and Safety Requirements

Look for speed tweaks, limit switches, overload shields, and strong brakes that fit your site. In most shops, gentle control and reliable stops matter more than raw speed.

Conclusion

An electric wire rope hoist is a staple in tons of industrial gigs. It delivers safe hauls, even motion, and keeps workflows humming. Knowing the ins and outs helps you snag gear that suits your setup and daily grind.

Through our KAWASAKI range, Apollo Hoist brings options honed from years on real job sites. With solid building know-how, custom fits, and designs geared for tough conditions, these hoists give you trusty lifts without extra fuss. For outfits that prize long-term reliability, it’s often the way to go.

FAQ

Q1: What makes a wire rope hoist better for heavy lifting than a chain hoist?

A: Wire rope hoists manage bigger weights and taller lifts more smoothly. They’re also tops for frequent hauls in busy plants.

Q2: Can KAWASAKI wire rope hoists be customized for special requirements?

A: Absolutely. We tweak voltage, speed, coatings, and seals to match your site’s quirks.

Q3: How often should an electric wire rope hoist be inspected?

A: It depends on how hard you push it and the surroundings. But regular looks at the rope, brakes, and switches are a must, especially in rough or corrosive areas.